hydraulic seal replacement.

Regular inspections during routine maintenance can identify potential issues before they become major problems Regular inspections during routine maintenance can identify potential issues before they become major problems

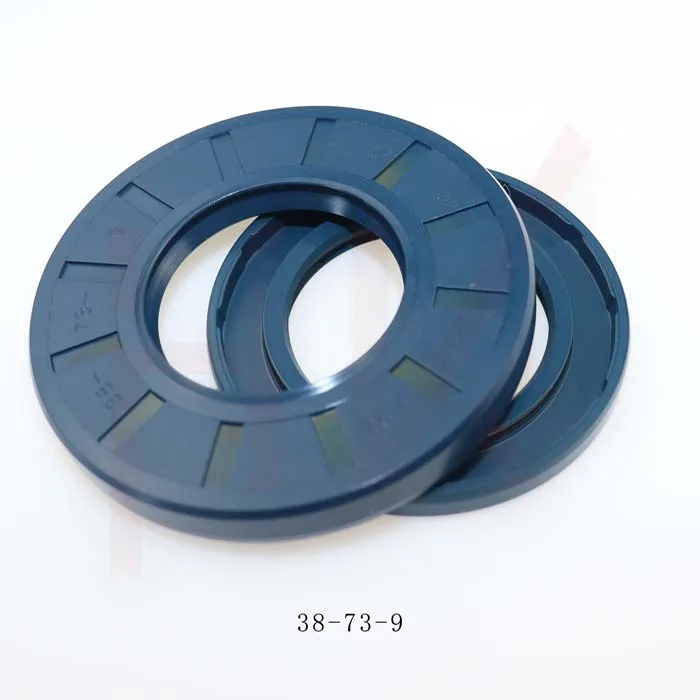

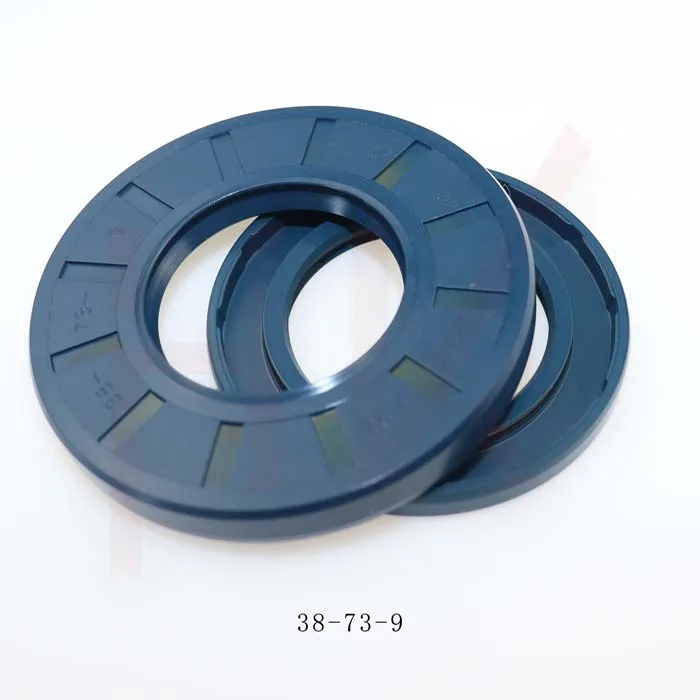

Regular inspections during routine maintenance can identify potential issues before they become major problems Regular inspections during routine maintenance can identify potential issues before they become major problems rear hub seal. If a seal is found to be damaged or worn, it should be replaced promptly to avoid more extensive and expensive repairs down the line. Replacing a rear hub seal is a relatively simple and inexpensive process compared to bearing replacement or hub rebuilds that might be necessary if the seal is neglected.

rear hub seal. If a seal is found to be damaged or worn, it should be replaced promptly to avoid more extensive and expensive repairs down the line. Replacing a rear hub seal is a relatively simple and inexpensive process compared to bearing replacement or hub rebuilds that might be necessary if the seal is neglected.

oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.

oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.

skeleton oil seal. By preventing oil loss, they ensure that the optimal amount of lubricant is always available, reducing the need for frequent top-ups and minimizing energy wastage due to inefficient lubrication.

skeleton oil seal. By preventing oil loss, they ensure that the optimal amount of lubricant is always available, reducing the need for frequent top-ups and minimizing energy wastage due to inefficient lubrication.