Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions

Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions pump seal oil.

pump seal oil.

Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions

Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions Moreover, it should possess good thermal stability and, resisting degradation even under high heat conditions pump seal oil.

pump seal oil.

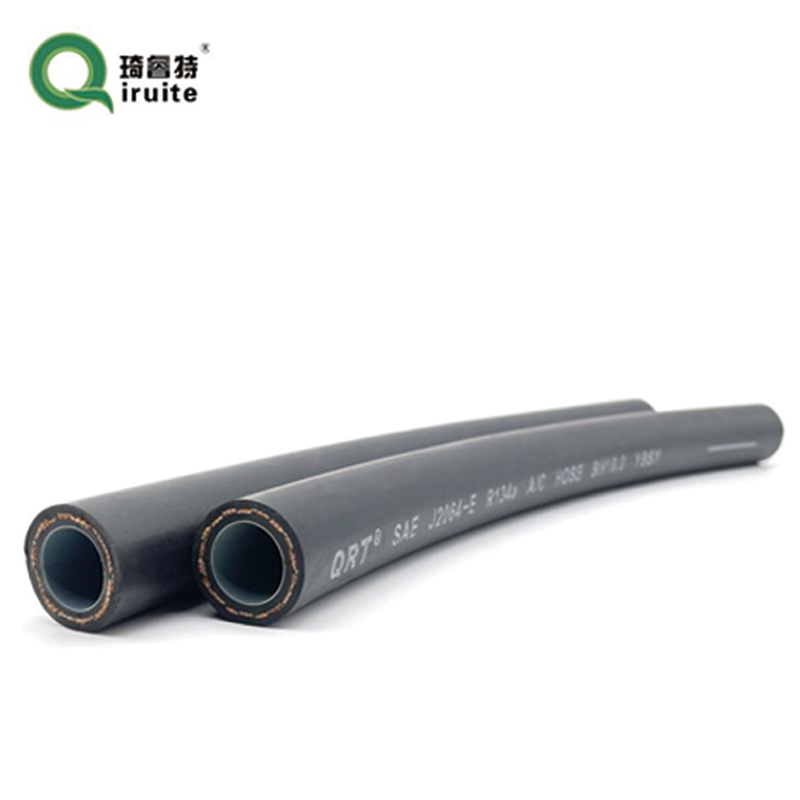

Unlike rigid hose pipes that can be challenging to handle, especially when trying to water plants in hard-to-reach areas, the ac hose pipe bends and twists effortlessly, allowing me to direct the water flow exactly where I want it Unlike rigid hose pipes that can be challenging to handle, especially when trying to water plants in hard-to-reach areas, the ac hose pipe bends and twists effortlessly, allowing me to direct the water flow exactly where I want it

Unlike rigid hose pipes that can be challenging to handle, especially when trying to water plants in hard-to-reach areas, the ac hose pipe bends and twists effortlessly, allowing me to direct the water flow exactly where I want it Unlike rigid hose pipes that can be challenging to handle, especially when trying to water plants in hard-to-reach areas, the ac hose pipe bends and twists effortlessly, allowing me to direct the water flow exactly where I want it ac hose pipe. This feature has been a game-changer, saving me both time and energy while ensuring that each plant receives an adequate amount of water.

ac hose pipe. This feature has been a game-changer, saving me both time and energy while ensuring that each plant receives an adequate amount of water.

plumbing slip coupling. First, clean the ends of the pipes to remove any dirt or debris. Then, screw the female connector onto one end of the pipe, and the male connector onto the other end. Press the two connectors together firmly until they click into place, creating a watertight seal.

plumbing slip coupling. First, clean the ends of the pipes to remove any dirt or debris. Then, screw the female connector onto one end of the pipe, and the male connector onto the other end. Press the two connectors together firmly until they click into place, creating a watertight seal.