Current location:Home > hyd cylinder seal kit >

hyd cylinder seal kit

2025-08-15 17:55

2025-08-15 17:29

2025-08-15 17:27

2025-08-15 17:09

2025-08-15 16:58

2025-08-15 16:45

2025-08-15 16:28

2025-08-15 16:26

2025-08-15 15:54

2025-08-15 15:18

Latest articles

The consequences of seal failure can be catastrophic; oil leaks can lead to contamination, reduced efficiency, increased wear and tear on moving parts, and potential safety hazards 22 40 7 oil seal. Therefore, the integrity of these seals is paramount. For instance, in an automotive engine, the oil seal ensures that the lubricant remains contained, preventing leaks that could not only damage the engine but also pose environmental risks.

22 40 7 oil seal. Therefore, the integrity of these seals is paramount. For instance, in an automotive engine, the oil seal ensures that the lubricant remains contained, preventing leaks that could not only damage the engine but also pose environmental risks.

22 40 7 oil seal. Therefore, the integrity of these seals is paramount. For instance, in an automotive engine, the oil seal ensures that the lubricant remains contained, preventing leaks that could not only damage the engine but also pose environmental risks.

22 40 7 oil seal. Therefore, the integrity of these seals is paramount. For instance, in an automotive engine, the oil seal ensures that the lubricant remains contained, preventing leaks that could not only damage the engine but also pose environmental risks.Moreover, the rigidity of the metal case ensures better dimensional stability, reducing the risk of deformation under pressure. This is particularly beneficial in dynamic sealing applications where the seal is subjected to continuous movement. The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment

The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment metal cased oil seals.

metal cased oil seals.

The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment

The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment The metal casing also improves the seal's performance in situations where there is a significant difference in temperature between the seal and the surrounding environment metal cased oil seals.

metal cased oil seals.To address these challenges, high pressure shaft seals are typically made from materials such as high-strength metals, ceramics, or specially formulated elastomers that can withstand high pressures and temperatures

high pressure shaft seals. These materials are often combined with advanced sealing technologies, such as spring-loaded designs or lip seals, to provide the necessary sealing power while minimizing friction and heat generation.

high pressure shaft seals. These materials are often combined with advanced sealing technologies, such as spring-loaded designs or lip seals, to provide the necessary sealing power while minimizing friction and heat generation.

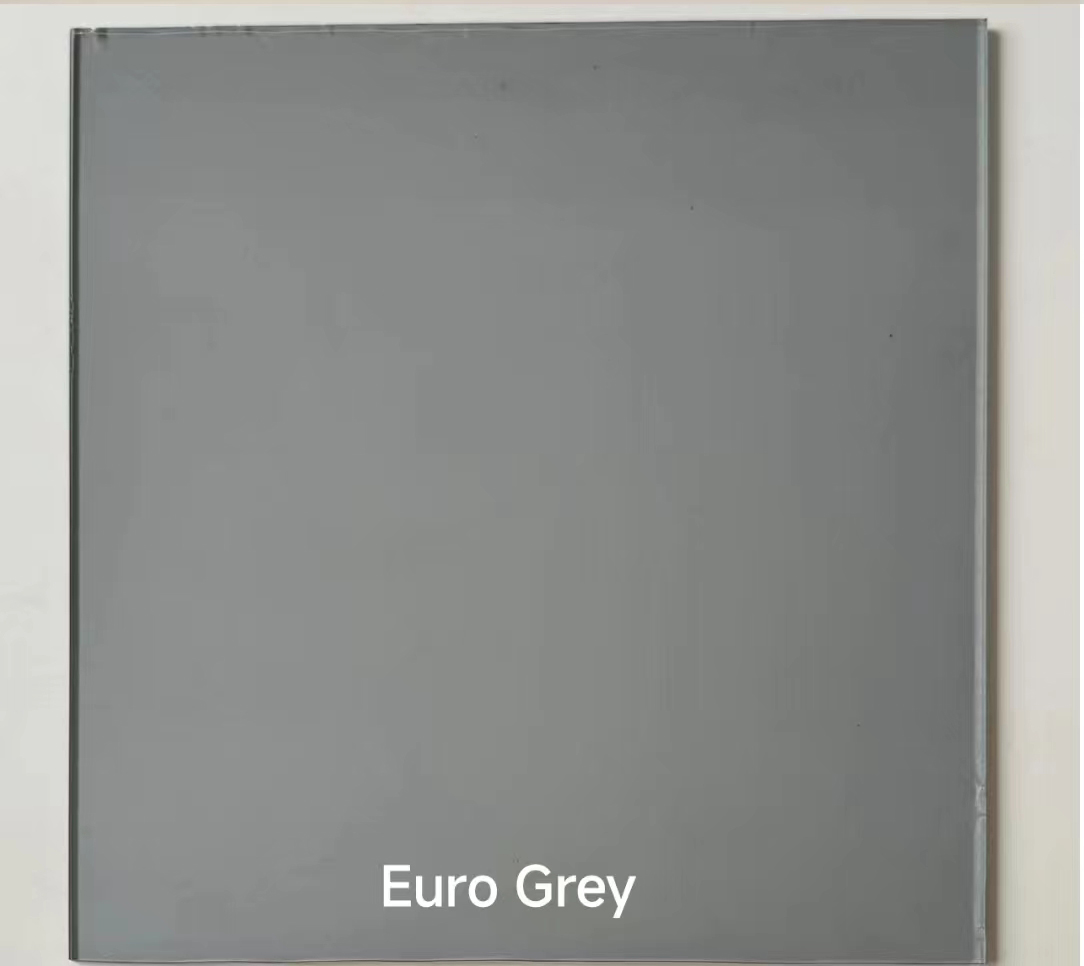

Another critical factor in determining the price of an IGU is the size of the unit insulated glass unit price. Larger units require more material and may need specialized installation techniques, which can escalate costs. Moreover, custom sizes or shapes often entail additional charges for the bespoke manufacturing process.

insulated glass unit price. Larger units require more material and may need specialized installation techniques, which can escalate costs. Moreover, custom sizes or shapes often entail additional charges for the bespoke manufacturing process.

insulated glass unit price. Larger units require more material and may need specialized installation techniques, which can escalate costs. Moreover, custom sizes or shapes often entail additional charges for the bespoke manufacturing process.

insulated glass unit price. Larger units require more material and may need specialized installation techniques, which can escalate costs. Moreover, custom sizes or shapes often entail additional charges for the bespoke manufacturing process.The size of the project will also impact the cost of frosted glass per square foot. Larger projects may be eligible for volume discounts, potentially reducing the overall cost of the glass

cost of frosted glass per square foot. Additionally, custom designs or complex patterns may increase the price of frosted glass.

cost of frosted glass per square foot. Additionally, custom designs or complex patterns may increase the price of frosted glass.

. He stood before the mirror, expecting to see his rugged exterior, but instead, he witnessed a vision of his own heart, filled with compassion and courage. This revelation led him to a path of healing and forgiveness, transforming his life from one of conflict to one of peace and honor.

. He stood before the mirror, expecting to see his rugged exterior, but instead, he witnessed a vision of his own heart, filled with compassion and courage. This revelation led him to a path of healing and forgiveness, transforming his life from one of conflict to one of peace and honor.