Current location:Home > hub oil seal >

hub oil seal

2025-08-14 13:17

2025-08-14 13:13

2025-08-14 12:56

2025-08-14 12:55

2025-08-14 12:38

2025-08-14 12:17

In power generation, high pressure shafts play a critical role in steam turbines. Here, they are subjected to steam at extremely high pressures, converting thermal energy into kinetic energy. The rotation of the shaft drives the generator, producing electricity. Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant high pressure shaft.

high pressure shaft.

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant high pressure shaft.

high pressure shaft.

...

2025-08-14 12:07

2025-08-14 11:50

2025-08-14 11:48

Latest articles

However, when a hub axle seal fails, the consequences can be dire. Leaked lubricant can lead to bearing failure, increased friction, and ultimately, costly repairs. More subtly, a compromised seal can allow corrosion to take hold, silently eroding the integrity of the axle from within. Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage

Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage hub axle seal.

hub axle seal.

Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage

Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage Thus, the lowly hub axle seal not only ensures the efficient function of the drivetrain but also protects against potentially catastrophic damage hub axle seal.

hub axle seal.In addition to its high load-carrying capacity, the 51118 bearing is also known for its high precision and durability. The rollers in the bearing are precision-ground to ensure smooth operation and long service life. This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common

This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common 51118 bearing.

51118 bearing.

This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common

This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common 51118 bearing.

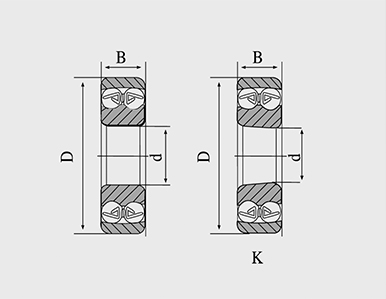

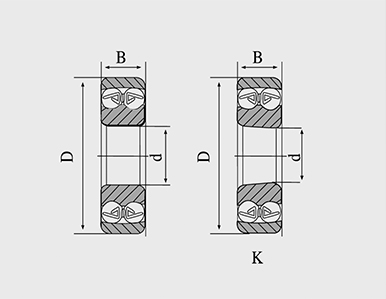

51118 bearing.Single row angular contact ball bearings are the most common type of angular contact bearings. They have a single row of balls positioned at an angle to the raceways, allowing them to accommodate axial loads in one direction

angular contact ball bearing single row. These bearings are often used in pairs to accommodate both radial and axial loads in either direction.

angular contact ball bearing single row. These bearings are often used in pairs to accommodate both radial and axial loads in either direction.

1 spherical plain bearing size chart pdf. Load requirements The magnitude and direction of the load acting on the bearing will determine the appropriate size and type of bearing required.

spherical plain bearing size chart pdf. Load requirements The magnitude and direction of the load acting on the bearing will determine the appropriate size and type of bearing required.

spherical plain bearing size chart pdf. Load requirements The magnitude and direction of the load acting on the bearing will determine the appropriate size and type of bearing required.

spherical plain bearing size chart pdf. Load requirements The magnitude and direction of the load acting on the bearing will determine the appropriate size and type of bearing required.In addition to its durability and load-bearing capacity, the 51312 thrust bearing is also known for its ease of installation and maintenance. With proper care and lubrication, this type of bearing can operate smoothly for extended periods without the need for frequent repairs or replacements

51312 thrust bearing. This makes it a cost-effective solution for industries that rely on heavy machinery and equipment to operate efficiently.

51312 thrust bearing. This makes it a cost-effective solution for industries that rely on heavy machinery and equipment to operate efficiently.