Current location:Home > shaft oil seal >

shaft oil seal

2025-08-16 05:44

2025-08-16 05:43

2025-08-16 05:42

2025-08-16 05:34

2025-08-16 04:47

2025-08-16 04:42

...

2025-08-16 04:12

2025-08-16 04:01

2025-08-16 03:57

2025-08-16 03:43

Latest articles

Made from high-quality materials, these seals often incorporate a rubber compound, such as Nitrile Butadiene Rubber (NBR), which offers excellent resistance to oil and heat. The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action

The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action 14x22x5 oil seal.

14x22x5 oil seal.

The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action

The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action The '5mm' thickness provides the necessary rigidity to withstand pressure while maintaining flexibility for effective sealing action 14x22x5 oil seal.

14x22x5 oil seal.When selecting a hydraulic oil seal, it's important to consider the specific requirements of your application hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.In addition to material selection, the design of the oil seal is also important

14 22 5 oil seal. Oil seals are available in various designs, such as lip seals, mechanical seals, and labyrinth seals. The design of the oil seal will depend on factors such as the speed of the equipment, the operating temperature, and the level of contamination present.

14 22 5 oil seal. Oil seals are available in various designs, such as lip seals, mechanical seals, and labyrinth seals. The design of the oil seal will depend on factors such as the speed of the equipment, the operating temperature, and the level of contamination present.

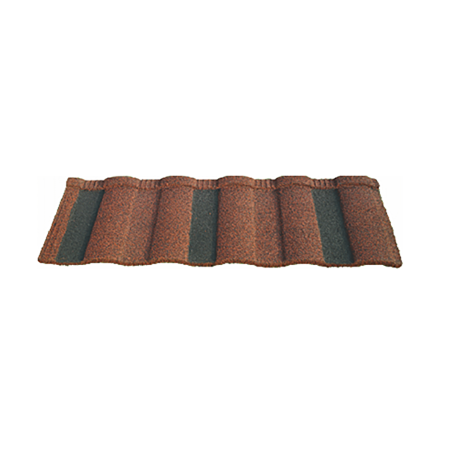

Ridge caps play a crucial role in any roofing system, particularly when installed with 3-tab shingles. These caps are designed to cover the ridge, or peak, of the roof where two slopes meet. Ridge caps protect this vulnerable area from water infiltration, which can lead to serious structural damage over time. By ensuring that the ridge cap is properly installed, homeowners can significantly extend the lifespan of their roofing system.

3 tab shingles ridge cap