hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

Current location:Home > Hebei Hankai gearbox seals >

Hebei Hankai gearbox seals

When selecting a hydraulic oil seal, it's important to consider the specific requirements of your application hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

hydraulic oil seal sizes. Factors such as temperature range, pressure rating, chemical compatibility, and shaft diameter all play a role in determining the appropriate seal size. It's also important to ensure that the seal you choose has the necessary features and properties to withstand the conditions of your application.

...

2025-08-16 15:39

2025-08-16 15:32

One of the key challenges in shaft oil seal design is to balance the competing demands of sealing effectiveness and shaft mobility. If the seal is too tight, it can impede the shaft's rotation, leading to increased friction and heat generation. On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively

On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively shaft oil seal. Therefore, careful consideration must be given to the seal's geometry, material properties, and installation process to ensure optimal performance.

shaft oil seal. Therefore, careful consideration must be given to the seal's geometry, material properties, and installation process to ensure optimal performance.

On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively

On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively On the other hand, if it is too loose, it may not be able to prevent oil leakage effectively shaft oil seal. Therefore, careful consideration must be given to the seal's geometry, material properties, and installation process to ensure optimal performance.

shaft oil seal. Therefore, careful consideration must be given to the seal's geometry, material properties, and installation process to ensure optimal performance.

...

2025-08-16 15:31

2025-08-16 15:08

2025-08-16 15:07

2025-08-16 14:58

2025-08-16 14:50

2025-08-16 14:37

In addition to preventing oil leakage, the oil seal TCV also helps to keep out contaminants such as dust, dirt, and water

oil seal tcv. These contaminants can cause damage to the shaft and bearings, leading to premature wear and failure of the equipment. By creating a tight seal between the shaft and housing, the TCV oil seal ensures that the internal components remain clean and well-lubricated, extending the overall lifespan of the machinery.

oil seal tcv. These contaminants can cause damage to the shaft and bearings, leading to premature wear and failure of the equipment. By creating a tight seal between the shaft and housing, the TCV oil seal ensures that the internal components remain clean and well-lubricated, extending the overall lifespan of the machinery.

...

2025-08-16 13:25

2025-08-16 13:20

Latest articles

The design of the tilt cylinder seal kit takes into account the rigorous demands placed on these seals in dynamic and often harsh environments. Materials used for manufacturing these seals are carefully selected for their durability, resistance to temperature extremes, and compatibility with various types of hydraulic fluids. Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications tilt cylinder seal kit.

tilt cylinder seal kit.

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications tilt cylinder seal kit.

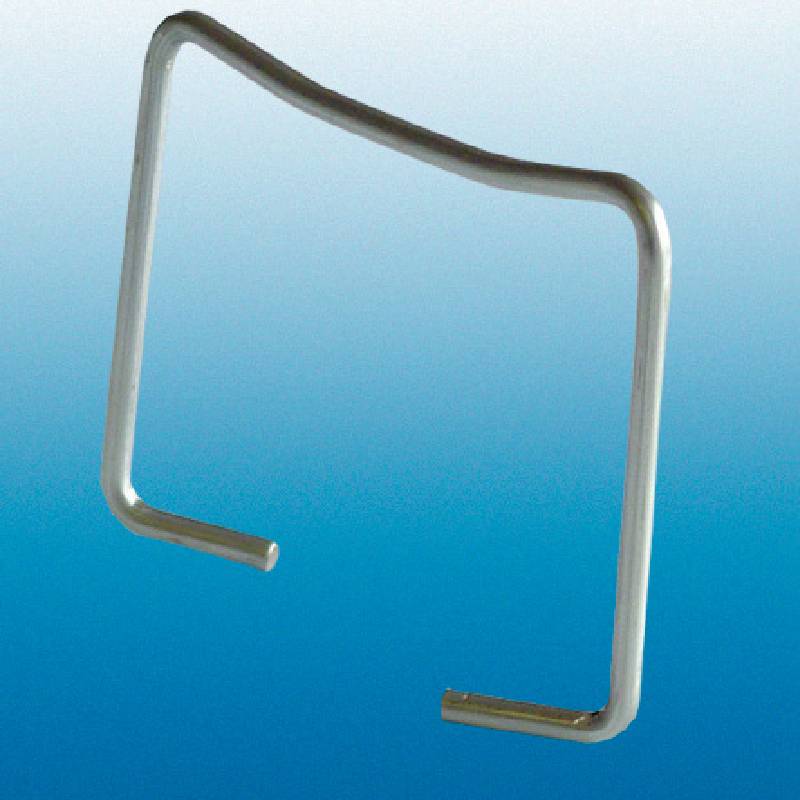

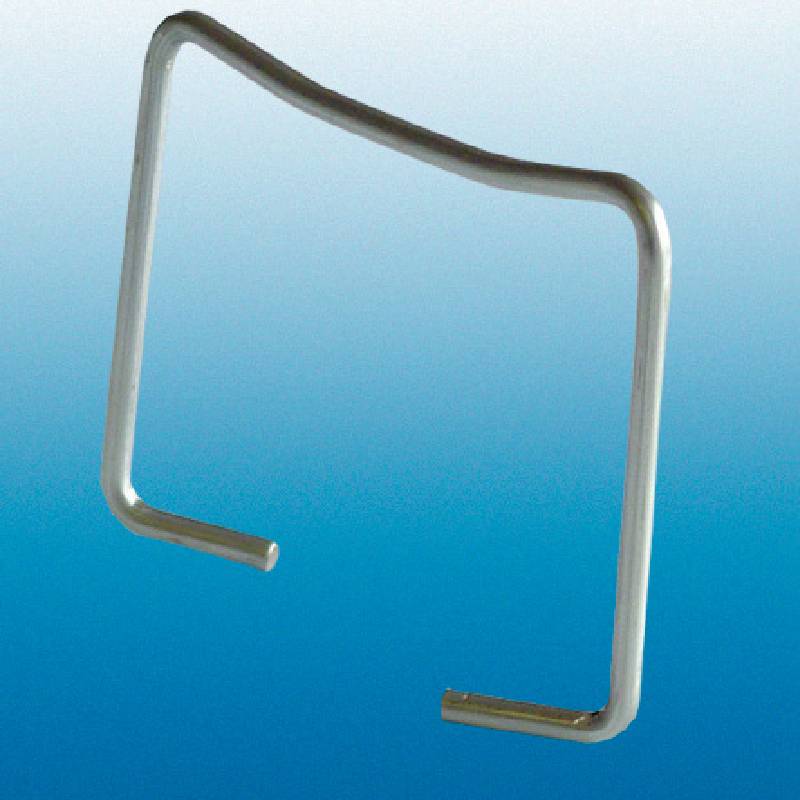

tilt cylinder seal kit.Another important function of rotary springs is to act as a shock absorber or vibration dampener in a system. By absorbing and dissipating energy from sudden impacts or fluctuations, rotary springs help to reduce wear and tear on other components and improve the overall performance and longevity of the system

rotary springs.

rotary springs.

However, it's essential to consider the impact on ride comfort 5 inch coil springs. While these springs do provide a firmer ride, modern coil spring design mitigates harshness, often incorporating progressive rates that are less stiff under light loads. This means that for daily driving, the 5% 20-inch coil springs can still deliver a comfortable ride, striking a balance between performance and practicality.

5 inch coil springs. While these springs do provide a firmer ride, modern coil spring design mitigates harshness, often incorporating progressive rates that are less stiff under light loads. This means that for daily driving, the 5% 20-inch coil springs can still deliver a comfortable ride, striking a balance between performance and practicality.

5 inch coil springs. While these springs do provide a firmer ride, modern coil spring design mitigates harshness, often incorporating progressive rates that are less stiff under light loads. This means that for daily driving, the 5% 20-inch coil springs can still deliver a comfortable ride, striking a balance between performance and practicality.

5 inch coil springs. While these springs do provide a firmer ride, modern coil spring design mitigates harshness, often incorporating progressive rates that are less stiff under light loads. This means that for daily driving, the 5% 20-inch coil springs can still deliver a comfortable ride, striking a balance between performance and practicality.