Current location:Home > hydraulic motor rebuild kit >

hydraulic motor rebuild kit

2025-08-14 08:57

The materials used in manufacturing hydraulic seals are also vital to their performance. Common materials include rubber compounds, polyurethane, and PTFE (Polytetrafluoroethylene). Each material offers different advantages and is selected based on the operating environment. For example, PTFE seals are highly resistant to chemicals and extreme temperatures, making them ideal for demanding applications.

hydraulic seal

...

2025-08-14 08:38

2025-08-14 08:35

2025-08-14 08:31

2025-08-14 07:45

2025-08-14 07:35

2025-08-14 07:33

In addition to protecting the wheel bearings, outer hub oil seals also help to maintain the proper lubrication levels within the wheel assembly

outer hub oil seal. Adequate lubrication is essential for reducing friction and heat buildup in the wheel bearings, which can lead to premature wear and failure. Outer hub oil seals help to retain the lubricant within the wheel assembly, ensuring that the bearings remain properly lubricated and can operate at peak performance.

outer hub oil seal. Adequate lubrication is essential for reducing friction and heat buildup in the wheel bearings, which can lead to premature wear and failure. Outer hub oil seals help to retain the lubricant within the wheel assembly, ensuring that the bearings remain properly lubricated and can operate at peak performance.

...

2025-08-14 06:59

2025-08-14 06:55

2025-08-14 06:43

Latest articles

Another advantage of galvanized mesh fencing is its low maintenance requirements galvanised mesh fencing. Unlike other types of fencing, this fence does not require regular painting or staining to maintain its appearance. The zinc coating provides natural protection against rust and corrosion, reducing the need for costly maintenance and repairs.

galvanised mesh fencing. Unlike other types of fencing, this fence does not require regular painting or staining to maintain its appearance. The zinc coating provides natural protection against rust and corrosion, reducing the need for costly maintenance and repairs.

galvanised mesh fencing. Unlike other types of fencing, this fence does not require regular painting or staining to maintain its appearance. The zinc coating provides natural protection against rust and corrosion, reducing the need for costly maintenance and repairs.

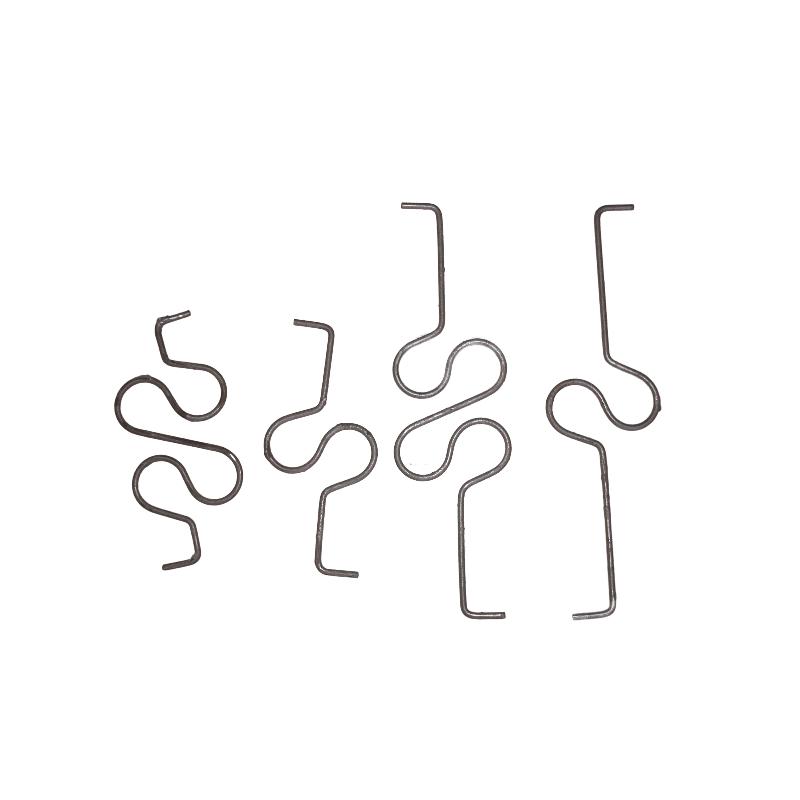

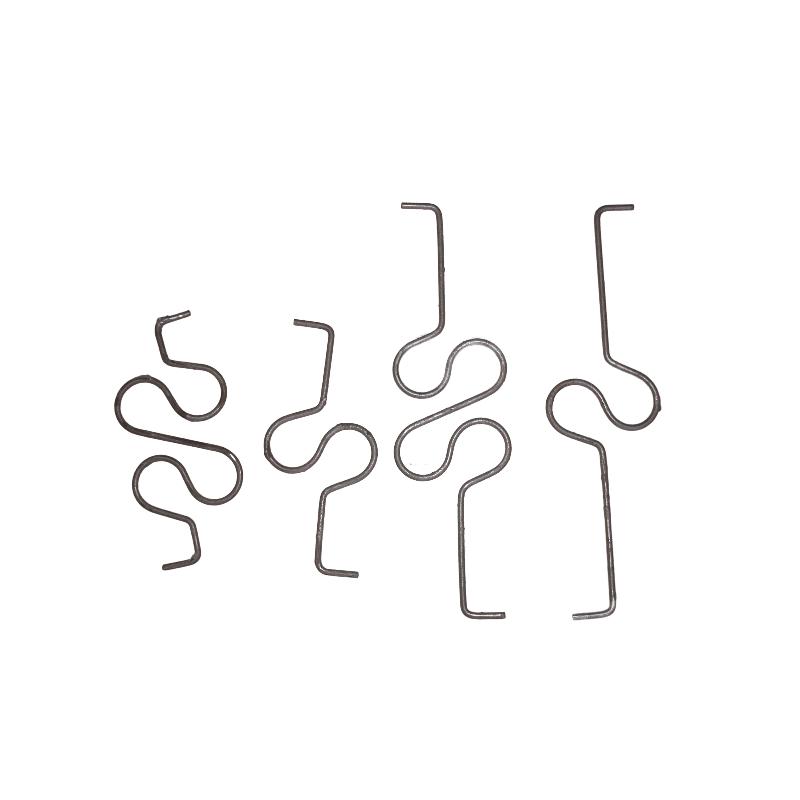

galvanised mesh fencing. Unlike other types of fencing, this fence does not require regular painting or staining to maintain its appearance. The zinc coating provides natural protection against rust and corrosion, reducing the need for costly maintenance and repairs.There are several types of 5-inch coil springs, including compression springs, extension springs, torsion springs, and wave springs. Compression springs are designed to resist compressive forces, while extension springs are designed to store and release energy as they extend and contract. Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections

Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections 5 inch coil springs.

5 inch coil springs.

Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections

Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections Torsion springs are used to apply torque to rotating components, and wave springs are specialized springs that use a wavy or corrugated design to provide a constant load over a range of deflections 5 inch coil springs.

5 inch coil springs.The aerospace industry also finds immense utility in HD Compression Springs. Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems

Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems hd compression spring. Their high-density construction ensures reliability under extreme conditions, crucial for safety in flight.

hd compression spring. Their high-density construction ensures reliability under extreme conditions, crucial for safety in flight.

Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems

Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems hd compression spring. Their high-density construction ensures reliability under extreme conditions, crucial for safety in flight.

hd compression spring. Their high-density construction ensures reliability under extreme conditions, crucial for safety in flight.