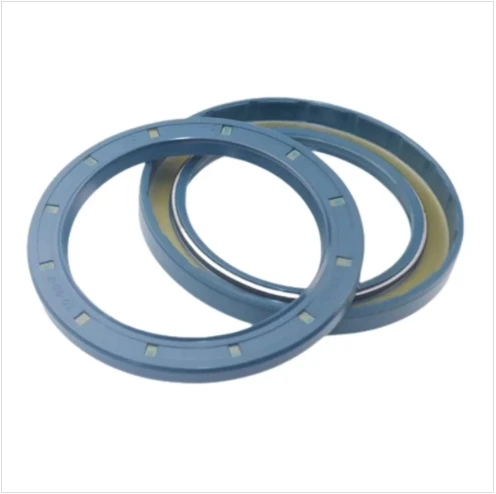

In industrial machinery, skeleton oil seals are utilized in gearboxes, pumps, and compressors

. These seals protect the internal components from environmental contaminants and ensure that the lubricants remain intact, thus reducing wear and tear on machinery. The robustness of skeleton oil seals makes them ideal for high-performance applications where reliability is paramount. Current location:Home > Hebei Hankai hydraulic oil seal kit >

Hebei Hankai hydraulic oil seal kit

...

2025-08-16 07:12

2025-08-16 06:56

2025-08-16 06:42

2025-08-16 06:37

2025-08-16 06:32

2025-08-16 06:05

2025-08-16 06:04

2025-08-16 05:53

Moreover, oil seal factories don't just produce standard seals; they also cater to customized requirements oil seal factory. They work closely with clients, understanding their unique needs, and create seals tailored to specific applications, be it for high-speed engines or deep-sea drilling equipment.

oil seal factory. They work closely with clients, understanding their unique needs, and create seals tailored to specific applications, be it for high-speed engines or deep-sea drilling equipment.

oil seal factory. They work closely with clients, understanding their unique needs, and create seals tailored to specific applications, be it for high-speed engines or deep-sea drilling equipment.

oil seal factory. They work closely with clients, understanding their unique needs, and create seals tailored to specific applications, be it for high-speed engines or deep-sea drilling equipment.

...

2025-08-16 05:51

2025-08-16 05:35

Latest articles

On the other hand, if contaminants find their way into the hub, they can mix with the lubricant, reducing its effectiveness and causing abrasive wear on the bearings. This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems

This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems wheel hub oil seal. Therefore, a robust and properly functioning wheel hub oil seal is vital for maintaining optimal vehicle performance and safety.

wheel hub oil seal. Therefore, a robust and properly functioning wheel hub oil seal is vital for maintaining optimal vehicle performance and safety.

This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems

This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems wheel hub oil seal. Therefore, a robust and properly functioning wheel hub oil seal is vital for maintaining optimal vehicle performance and safety.

wheel hub oil seal. Therefore, a robust and properly functioning wheel hub oil seal is vital for maintaining optimal vehicle performance and safety.Polyurethane is another popular material used in hydraulic cylinder seal kits. Polyurethane seals are known for their exceptional wear resistance, high flexibility, and excellent sealing properties. These seals are ideal for applications where there is a need for high pressure and high-speed operation. Polyurethane seals are also resistant to abrasion, making them suitable for heavy-duty applications.

Another technique involves the use of durable water repellent (DWR) treatments. These treatments are applied to the outer surface of wool fabrics to create a protective layer that causes water to bead up and roll off. While DWR treatments can wear off over time, they are a valuable addition to the waterproofing arsenal and can be reapplied as needed.

waterproof wool hunting clothes