Current location:Home > what is the function of oil seal >

what is the function of oil seal

2025-08-16 16:40

2025-08-16 16:33

2025-08-16 16:29

2025-08-16 15:37

2025-08-16 15:35

2025-08-16 14:55

2025-08-16 14:37

2025-08-16 14:34

2025-08-16 14:15

2025-08-16 14:12

Latest articles

When the supply water strikes the valve, it creates a sudden pressure surge that forces the ram closed, trapping the water. As the pressure subsides, the ram opens, allowing the trapped water to escape through the delivery valve, propelling water up the delivery pipe. Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats

Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats hydraulic ram kit.

hydraulic ram kit.

Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats

Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats Simultaneously, the suction valve opens, allowing new water to enter and the cycle repeats hydraulic ram kit.

hydraulic ram kit.Regular inspection and replacement of the wiper seal is essential for maintaining optimal vehicle performance and ensuring driver safety. It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions

It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions wiper seal. During this time, it is also a good idea to inspect the wiper blades for wear and tear, as these can also affect visibility and performance.

wiper seal. During this time, it is also a good idea to inspect the wiper blades for wear and tear, as these can also affect visibility and performance.

It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions

It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions It is recommended to replace the wiper seal every 6 to 12 months, depending on usage and environmental conditions wiper seal. During this time, it is also a good idea to inspect the wiper blades for wear and tear, as these can also affect visibility and performance.

wiper seal. During this time, it is also a good idea to inspect the wiper blades for wear and tear, as these can also affect visibility and performance.In addition to preventing leaks and contamination, hub seals also help to reduce friction and heat generation between moving parts

hub seal. This is crucial for maintaining the efficiency and reliability of machines, as excessive friction can lead to overheating, increased energy consumption, and premature wear. By effectively sealing the interface between two surfaces, hub seals enable smooth operation and optimal performance.

hub seal. This is crucial for maintaining the efficiency and reliability of machines, as excessive friction can lead to overheating, increased energy consumption, and premature wear. By effectively sealing the interface between two surfaces, hub seals enable smooth operation and optimal performance.

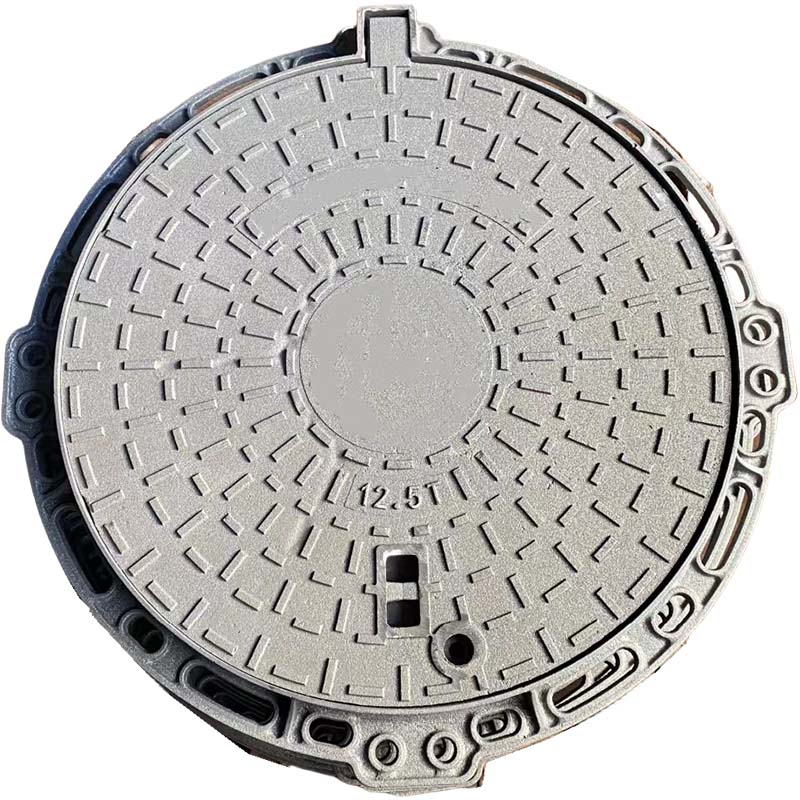

One of the primary materials used for manufacturing 600 x 500 manhole covers is cast iron, known for its durability and strength. These covers must withstand the heavy loads of traffic while maintaining their structural integrity. Advanced manufacturing techniques, including ductile iron and composite materials, are also making their way into the market. These innovations contribute to a reduction in weight while enhancing resistance to corrosion, therefore extending the lifespan of the covers.

600 x 500 manhole cover