Current location:Home > custom made oil seals >

custom made oil seals

2025-08-15 22:30

2025-08-15 22:18

2025-08-15 22:01

2025-08-15 21:56

2025-08-15 21:52

2025-08-15 21:15

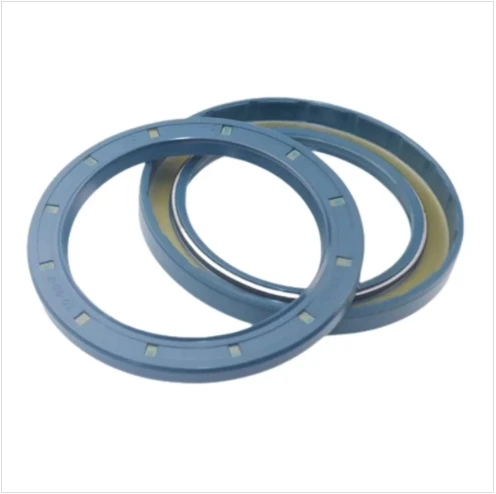

The installation process of hub oil seals requires great care and attention to detail hub oil seal. Incorrect installation can lead to premature failure, causing oil leaks and potentially damaging the bearings. Regular maintenance and inspection of these seals are essential to ensure their effectiveness, especially in harsh operating conditions or in vehicles subjected to heavy loads.

hub oil seal. Incorrect installation can lead to premature failure, causing oil leaks and potentially damaging the bearings. Regular maintenance and inspection of these seals are essential to ensure their effectiveness, especially in harsh operating conditions or in vehicles subjected to heavy loads.

hub oil seal. Incorrect installation can lead to premature failure, causing oil leaks and potentially damaging the bearings. Regular maintenance and inspection of these seals are essential to ensure their effectiveness, especially in harsh operating conditions or in vehicles subjected to heavy loads.

hub oil seal. Incorrect installation can lead to premature failure, causing oil leaks and potentially damaging the bearings. Regular maintenance and inspection of these seals are essential to ensure their effectiveness, especially in harsh operating conditions or in vehicles subjected to heavy loads.

...

2025-08-15 21:09

2025-08-15 20:55

...

2025-08-15 19:59

2025-08-15 19:51

Latest articles

Lastly, the 10% pertains to the recommended periodic inspection frequency. Industry experts advise checking oil seals at least every 10% of their expected service life Industry experts advise checking oil seals at least every 10% of their expected service life Industry experts advise checking oil seals at least every 10% of their expected service life Industry experts advise checking oil seals at least every 10% of their expected service life

Industry experts advise checking oil seals at least every 10% of their expected service life Industry experts advise checking oil seals at least every 10% of their expected service life 35 72 10 oil seal. This proactive approach helps identify any signs of wear or damage early on, allowing for timely repairs or replacements, thereby averting potential system failures.

35 72 10 oil seal. This proactive approach helps identify any signs of wear or damage early on, allowing for timely repairs or replacements, thereby averting potential system failures.

Industry experts advise checking oil seals at least every 10% of their expected service life Industry experts advise checking oil seals at least every 10% of their expected service life

Industry experts advise checking oil seals at least every 10% of their expected service life Industry experts advise checking oil seals at least every 10% of their expected service life 35 72 10 oil seal. This proactive approach helps identify any signs of wear or damage early on, allowing for timely repairs or replacements, thereby averting potential system failures.

35 72 10 oil seal. This proactive approach helps identify any signs of wear or damage early on, allowing for timely repairs or replacements, thereby averting potential system failures.In addition to its role in preventing oil leakage and maintaining lubrication, the oil seal 12 22 5 also helps to protect the machinery from external environmental factors. It can withstand high temperatures, pressure, and exposure to chemicals, ensuring that the equipment operates effectively in various conditions

oil seal 12 22 5.

oil seal 12 22 5.

Here are the steps to follow

Here are the steps to follow