Current location:Home > hydraulic pump oil seal >

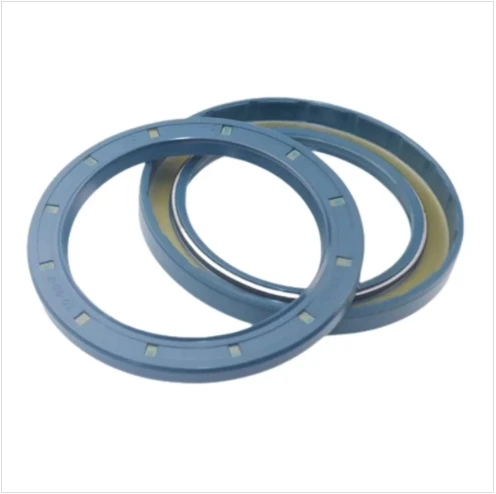

hydraulic pump oil seal

2025-08-18 00:48

2025-08-18 00:46

2025-08-18 00:09

2025-08-17 23:26

2025-08-17 23:15

2025-08-17 22:51

2025-08-17 22:43

2025-08-17 22:38

2025-08-17 22:20

2025-08-17 22:14

Latest articles

The choice of the right oil seal is crucial for optimal performance. Factors such as operating pressure, temperature, speed, and the type of fluid used need to be considered. A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system

A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system hydraulic cylinder oil seal.

hydraulic cylinder oil seal.

A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system

A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system A poorly selected seal can lead to premature failure, causing leaks, reduced efficiency, and potential damage to the hydraulic system hydraulic cylinder oil seal.

hydraulic cylinder oil seal.After the old seal has been removed, the next step is to clean the area where the new seal will be installed

hydraulic seal replacement. It is crucial to ensure that the seal fits properly and is free from any dirt or debris that could affect its performance. Once the area is clean, the new seal can be installed following the manufacturer's guidelines.

hydraulic seal replacement. It is crucial to ensure that the seal fits properly and is free from any dirt or debris that could affect its performance. Once the area is clean, the new seal can be installed following the manufacturer's guidelines.

The design of PU oil seals also plays a significant role in their functionality pu oil seal. They often feature a-like structure that creates a tight seal against the mating surface, preventing the leakage of oil or other fluids. This design, combined with the elastic memory of polyurethane, allows the seal to recover its original shape after compression, maintaining a consistent seal even under fluctuating pressures.

pu oil seal. They often feature a-like structure that creates a tight seal against the mating surface, preventing the leakage of oil or other fluids. This design, combined with the elastic memory of polyurethane, allows the seal to recover its original shape after compression, maintaining a consistent seal even under fluctuating pressures.

pu oil seal. They often feature a-like structure that creates a tight seal against the mating surface, preventing the leakage of oil or other fluids. This design, combined with the elastic memory of polyurethane, allows the seal to recover its original shape after compression, maintaining a consistent seal even under fluctuating pressures.

pu oil seal. They often feature a-like structure that creates a tight seal against the mating surface, preventing the leakage of oil or other fluids. This design, combined with the elastic memory of polyurethane, allows the seal to recover its original shape after compression, maintaining a consistent seal even under fluctuating pressures.One of the critical aspects of a U type nail factory is its commitment to innovation and technology. Advanced manufacturing techniques such as automated stamping or cold forming are employed to ensure consistent quality and high production rates. Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable

Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable u type nail factory.

u type nail factory.

Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable

Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable Moreover, these factories often invest in research and development to improve the design further, making the U type nail even more efficient and durable u type nail factory.

u type nail factory.