The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies

The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies hyd cylinder seals.

hyd cylinder seals.

The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies

The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies hyd cylinder seals.

hyd cylinder seals.

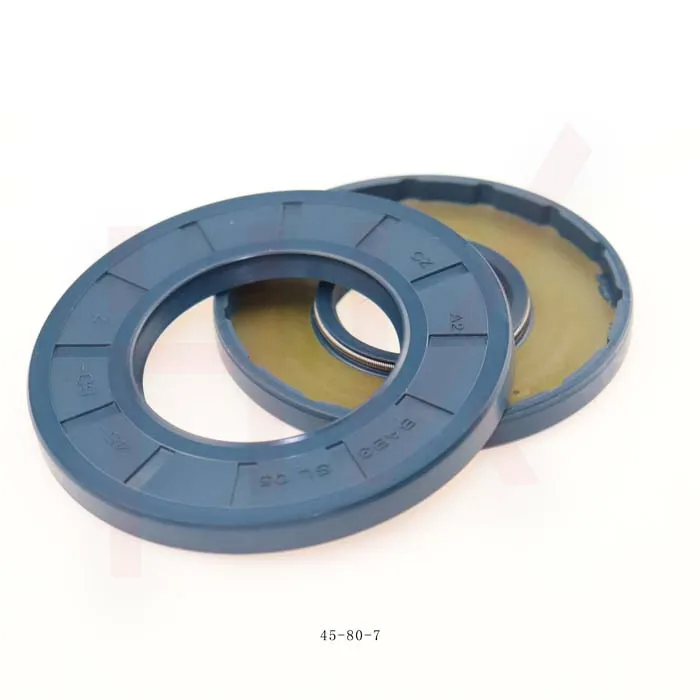

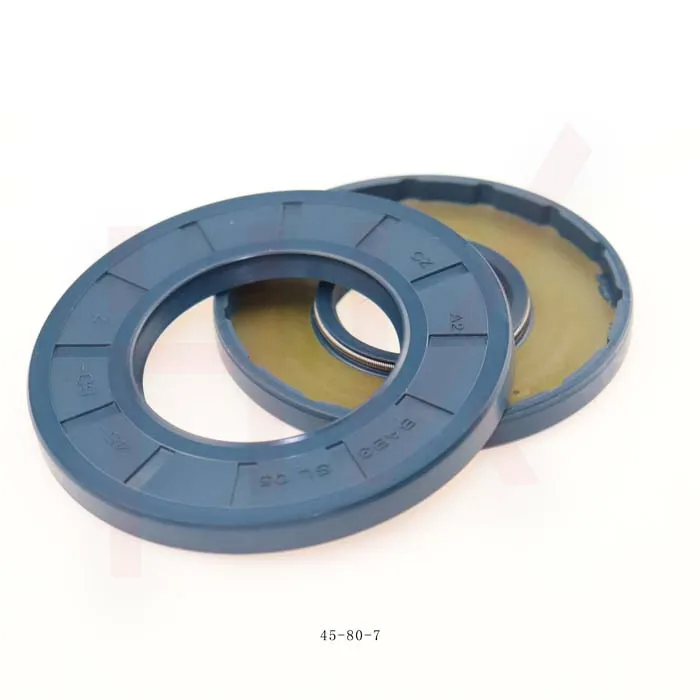

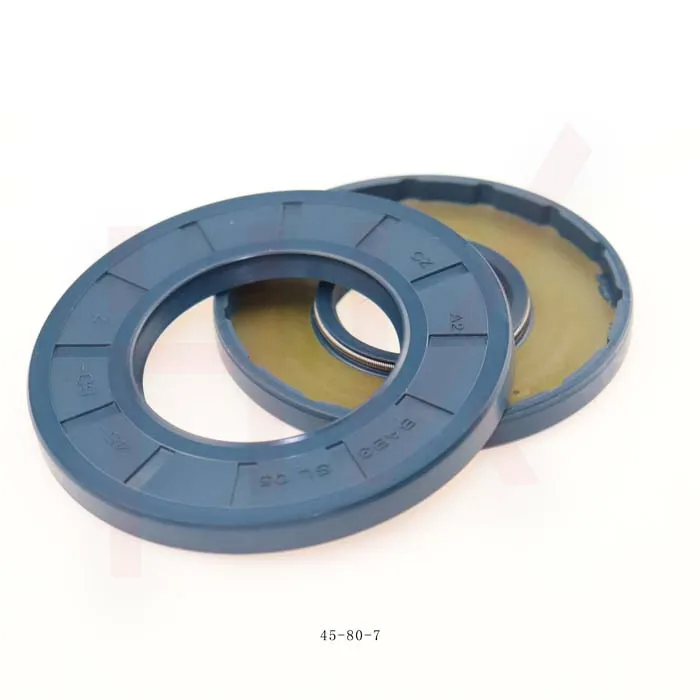

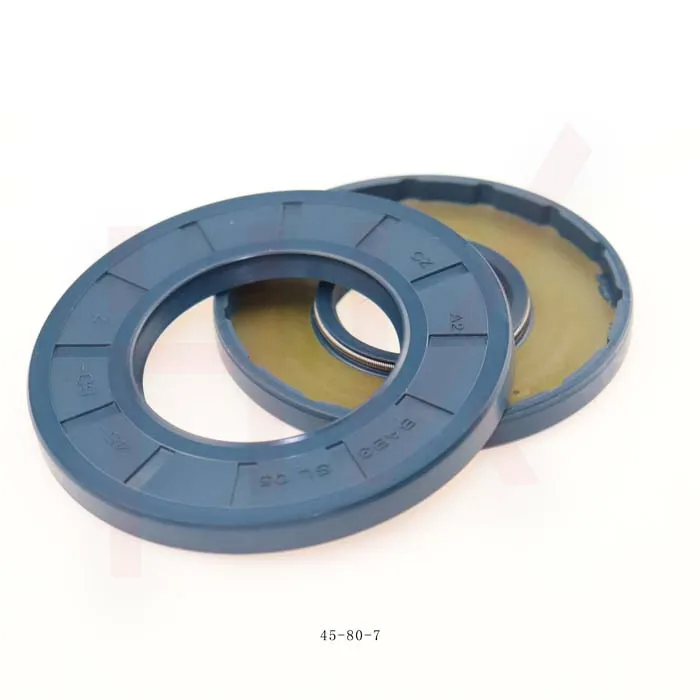

industrial oil seals. There are various types of oil seals available, including lip seals, scraper seals, and mechanical face seals, each tailored to suit different requirements.

industrial oil seals. There are various types of oil seals available, including lip seals, scraper seals, and mechanical face seals, each tailored to suit different requirements.