Current location:Home > Hebei Hankai hydraulic oil seal sizes >

Hebei Hankai hydraulic oil seal sizes

2025-08-14 22:43

2025-08-14 22:40

2025-08-14 22:33

2025-08-14 22:27

2025-08-14 22:19

2025-08-14 22:03

2025-08-14 22:00

2025-08-14 21:53

2025-08-14 21:11

2025-08-14 20:28

Latest articles

Maintenance of rotary shaft oil seals involves regular inspections for signs of wear, such as cracking, deformation, or excessive leakage rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.

rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.

rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.

rotary shaft oil seals. Early detection of these issues can prevent more significant problems down the line. Additionally, proper lubrication of the shaft and seal can significantly enhance their lifespan and performance.Another advantage of oil seals is their ability to protect against contamination oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.

oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.

oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.

oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.Integration of such systems requires a strategic approach

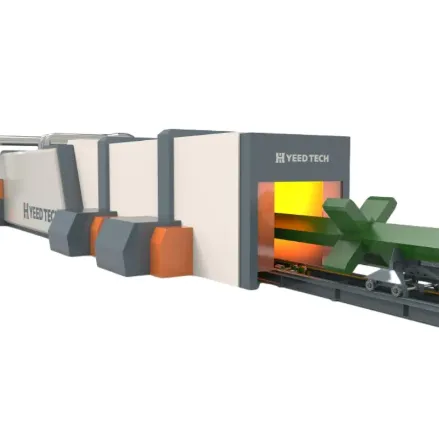

. It involves a thorough analysis of existing production lines, a clear understanding of desired outcomes, and careful planning to minimize disruption. Companies that have successfully transitioned to automated spray coating systems often report significant improvements in quality assurance processes, facilitating smoother operations and enhancing customer satisfaction.Furthermore, the adaptability of these systems is a point of expertise worthy of note. Sectors such as furniture manufacturing and heavy machinery have unique requirements; automatic systems can be programmed for a myriad of settings, accommodating different paint viscosities and surface types. The expertise embedded in these solutions is evident—they offer industry-specific customizations, which ensure optimal performance and quality.

automatic paint spraying equipment