Always refer to the manufacturer's guidelines or consult a professional if unsure Always refer to the manufacturer's guidelines or consult a professional if unsure

Always refer to the manufacturer's guidelines or consult a professional if unsure Always refer to the manufacturer's guidelines or consult a professional if unsure bottle jack repair kits.

bottle jack repair kits.

Always refer to the manufacturer's guidelines or consult a professional if unsure Always refer to the manufacturer's guidelines or consult a professional if unsure

Always refer to the manufacturer's guidelines or consult a professional if unsure Always refer to the manufacturer's guidelines or consult a professional if unsure bottle jack repair kits.

bottle jack repair kits.

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant high pressure shaft.

high pressure shaft.

In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication

In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication In vehicles, for instance, they are crucial in maintaining the health of wheel bearings, preventing brake dust and road debris from entering and compromising the lubrication hub grease seal. In industrial machinery, they protect critical components from harsh environments, ensuring uninterrupted operation and minimizing maintenance downtime.

hub grease seal. In industrial machinery, they protect critical components from harsh environments, ensuring uninterrupted operation and minimizing maintenance downtime.

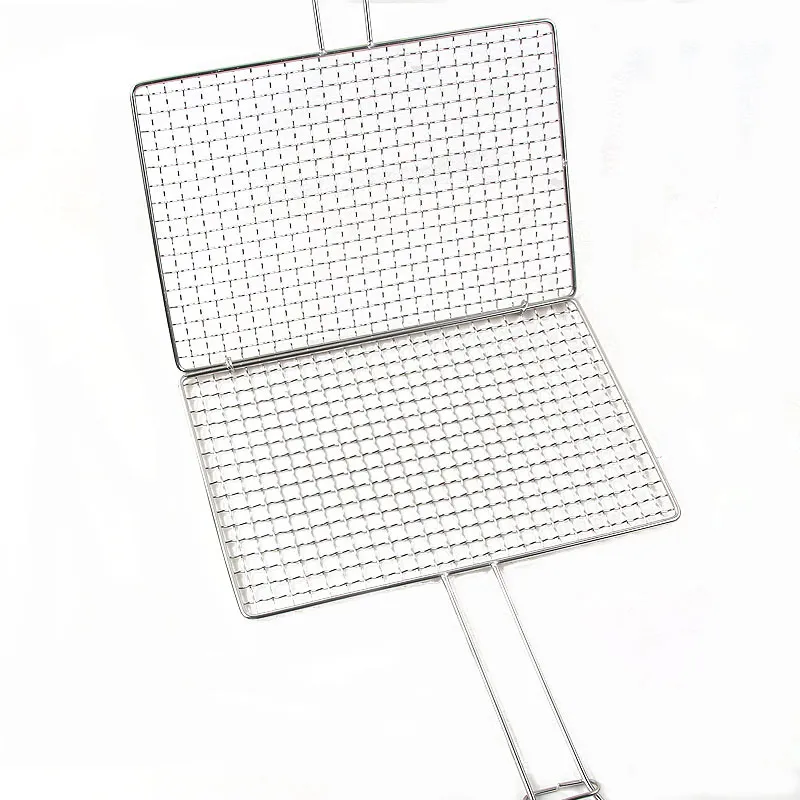

A tripod cooking grate typically consists of three sturdy legs, supporting a flat cooking surface suspended above the fire. This design allows for stability and versatility, making it an ideal choice for various cooking styles. Whether you’re grilling, boiling, or baking, a tripod grate can accommodate different cookware, such as pots, pans, and Dutch ovens. The adjustable height also means you can control the heat intensity, giving you perfect results every time.

Additionally, using a cooling rack can help maintain the integrity of the toppings. When a pizza is left to sit on a hot surface, the steam created can cause the cheese and toppings to slide off, resulting in a messy presentation. A cooling rack elevates the pizza, allowing for even airflow around it. This not only helps to prevent sogginess but also keeps the toppings in place, making your pizza look as good as it tastes.

One of the primary benefits of using proofing racks is their ability to streamline the proofing process. These racks often come equipped with features such as adjustable shelves, ventilation, and sometimes even integrated heating elements. This versatility allows bakers to proof multiple batches of dough simultaneously, thus enhancing efficiency in a busy bakery setting. With a proofing rack, bakers can ensure that all their dough rises evenly and consistently, leading to uniformly baked products.