hydraulic oil seal types.

inner hub seal. Some seals are made of rubber or plastic, while others are made of more durable materials such as metal or synthetic rubber. The choice of seal will depend on factors such as the type of machinery, the operating conditions, and the level of sealing required.

inner hub seal. Some seals are made of rubber or plastic, while others are made of more durable materials such as metal or synthetic rubber. The choice of seal will depend on factors such as the type of machinery, the operating conditions, and the level of sealing required.

pu oil seal. Marine Protecting boat engines and hydraulic systems from water and contaminants.

pu oil seal. Marine Protecting boat engines and hydraulic systems from water and contaminants.

The materials used in manufacturing hydraulic seals are also vital to their performance. Common materials include rubber compounds, polyurethane, and PTFE (Polytetrafluoroethylene). Each material offers different advantages and is selected based on the operating environment. For example, PTFE seals are highly resistant to chemicals and extreme temperatures, making them ideal for demanding applications.

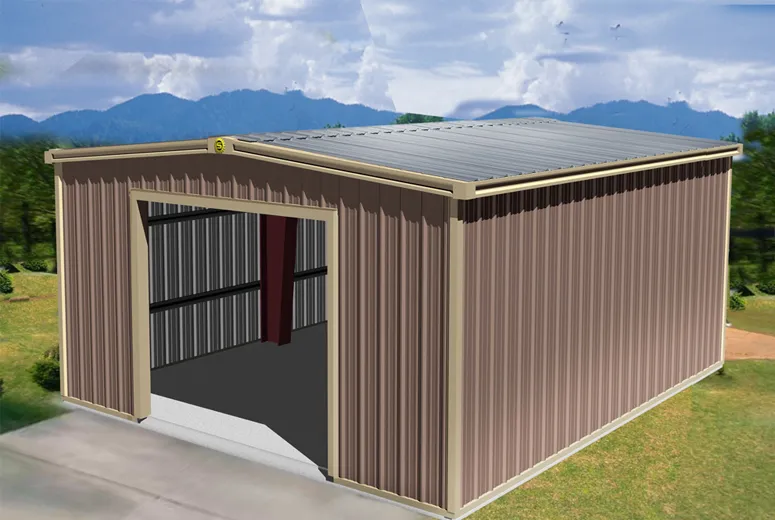

Moreover, metal structures require significantly less maintenance. Regular inspections and occasional cleaning are usually all that is needed to keep a metal building in prime condition. This durability translates into cost savings over time, as homeowners can avoid the frequent repair and replacement costs associated with other building materials.

Material costs are another substantial part of the operating expenses. Steel prices fluctuate based on market demand, production costs, and global supply chain issues. Workshop owners must develop strategies to manage these costs effectively, whether through long-term supplier contracts to lock in prices or by diversifying sources of materials.