Current location:Home > hydraulic motor seals >

hydraulic motor seals

2025-08-15 08:47

2025-08-15 08:38

2025-08-15 08:37

2025-08-15 08:32

2025-08-15 08:30

2025-08-15 08:27

2025-08-15 08:04

2025-08-15 07:58

2025-08-15 07:39

Furthermore, dust lip seals also contribute to the overall efficiency and reliability of machinery

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

...

2025-08-15 06:14

Latest articles

One of the key challenges in designing high pressure rotary shaft seals is managing heat generation. The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan

The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan high pressure rotary shaft seals. To counter this, advanced designs incorporate cooling channels or use thermally stable materials to dissipate heat effectively.

high pressure rotary shaft seals. To counter this, advanced designs incorporate cooling channels or use thermally stable materials to dissipate heat effectively.

The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan

The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan The friction between the rotating shaft and the seal can lead to significant heat buildup, which can degrade the seal's performance and lifespan high pressure rotary shaft seals. To counter this, advanced designs incorporate cooling channels or use thermally stable materials to dissipate heat effectively.

high pressure rotary shaft seals. To counter this, advanced designs incorporate cooling channels or use thermally stable materials to dissipate heat effectively.In terms of effectiveness, both dust seals and oil seals are important for protecting machinery and equipment. Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems

Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.

dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.

Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems

Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems Dust seals are crucial for preventing wear and tear caused by solid contaminants, while oil seals are necessary for maintaining the integrity of lubrication systems dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.

dust seal vs oil seal. However, the choice between the two ultimately depends on the specific requirements of the machinery and the environment in which it operates.Moreover, mesh welded panels offer superior strength and durability. The interlocking wire mesh structure provides excellent resistance to bending, twisting, and shear forces, making these panels ideal for use in high-stress applications such as earthquake-prone regions or heavy industrial environments. Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting

Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting mesh welded panels.

mesh welded panels.

Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting

Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting Additionally, the panels can be coated with a variety of materials, including paint, plaster, or even brick, to provide a finished surface that is both aesthetically pleasing and long-lasting mesh welded panels.

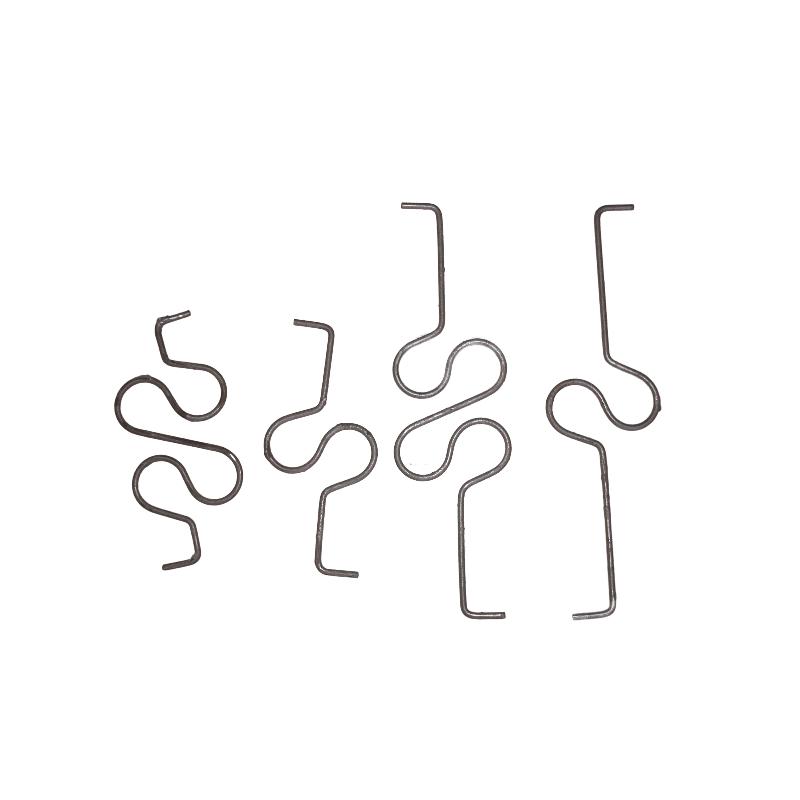

mesh welded panels.In addition to springs, spring steel coils are also used in the production of a wide range of other products. They are commonly used in the manufacture of saw blades, knives, and tools due to their high strength and durability. Spring steel coils are also used in the construction industry to reinforce concrete structures and provide additional support and stability

spring steel coil.

spring steel coil.