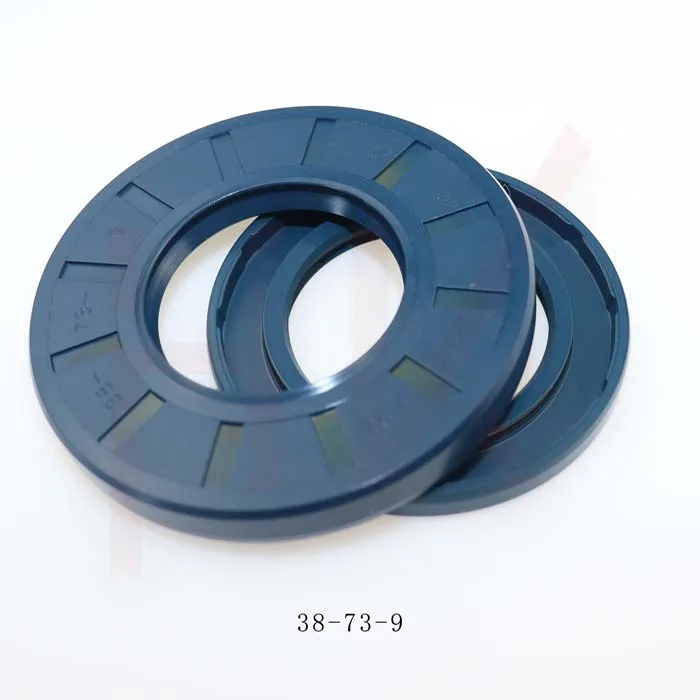

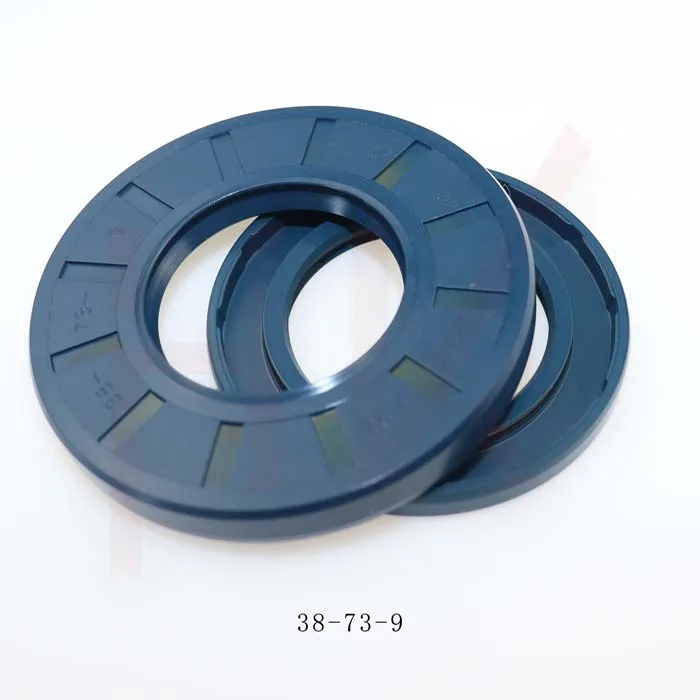

hydraulic seal replacement.

Proper alignment and lubrication of the seal are essential to ensure a tight and secure fit, preventing leaks and maximizing the seal's effectiveness Proper alignment and lubrication of the seal are essential to ensure a tight and secure fit, preventing leaks and maximizing the seal's effectiveness

Proper alignment and lubrication of the seal are essential to ensure a tight and secure fit, preventing leaks and maximizing the seal's effectiveness Proper alignment and lubrication of the seal are essential to ensure a tight and secure fit, preventing leaks and maximizing the seal's effectiveness 30x52x7 seal.

30x52x7 seal.

seals for agriculture. Many fishing and aquaculture operations rely on healthy ocean ecosystems to thrive, and seals are an important part of that ecosystem. By helping to maintain the balance of these systems, seals indirectly support the economic well-being of coastal communities.

seals for agriculture. Many fishing and aquaculture operations rely on healthy ocean ecosystems to thrive, and seals are an important part of that ecosystem. By helping to maintain the balance of these systems, seals indirectly support the economic well-being of coastal communities.