Current location:Home > rear hub oil seal >

rear hub oil seal

2025-08-14 04:27

2025-08-14 04:16

2025-08-14 04:08

2025-08-14 03:13

2025-08-14 03:09

2025-08-14 03:09

When selecting a seal kit for a hydraulic motor, there are a few key factors to consider. First and foremost, it is essential to choose a kit that is compatible with the make and model of the motor in question. Using the wrong seals can result in improper fitment and compromised performance. Additionally, it is crucial to ensure that the seal kit is made from high-quality materials that can withstand the high pressures and temperatures experienced in hydraulic systems

seal kit for hydraulic motor.

seal kit for hydraulic motor.

...

2025-08-14 02:34

2025-08-14 02:27

2025-08-14 02:13

2025-08-14 02:10

Latest articles

The first step in the rebuild process is to dismantle the hydraulic cylinder, carefully removing each part for inspection. Damaged or worn components are identified and replaced with the new ones from the kit. This may involve cleaning and honing the cylinder bore, installing new seals, and replacing worn piston rods or bushes. The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild

The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild engine hoist hydraulic cylinder rebuild kit.

engine hoist hydraulic cylinder rebuild kit.

The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild

The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild engine hoist hydraulic cylinder rebuild kit.

engine hoist hydraulic cylinder rebuild kit.In power generation, high pressure shafts play a critical role in steam turbines. Here, they are subjected to steam at extremely high pressures, converting thermal energy into kinetic energy. The rotation of the shaft drives the generator, producing electricity. Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant high pressure shaft.

high pressure shaft.

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant

Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant Any malfunction in the high pressure shaft can lead to significant downtime and loss of productivity, emphasizing its importance in maintaining the overall operational efficiency of the power plant high pressure shaft.

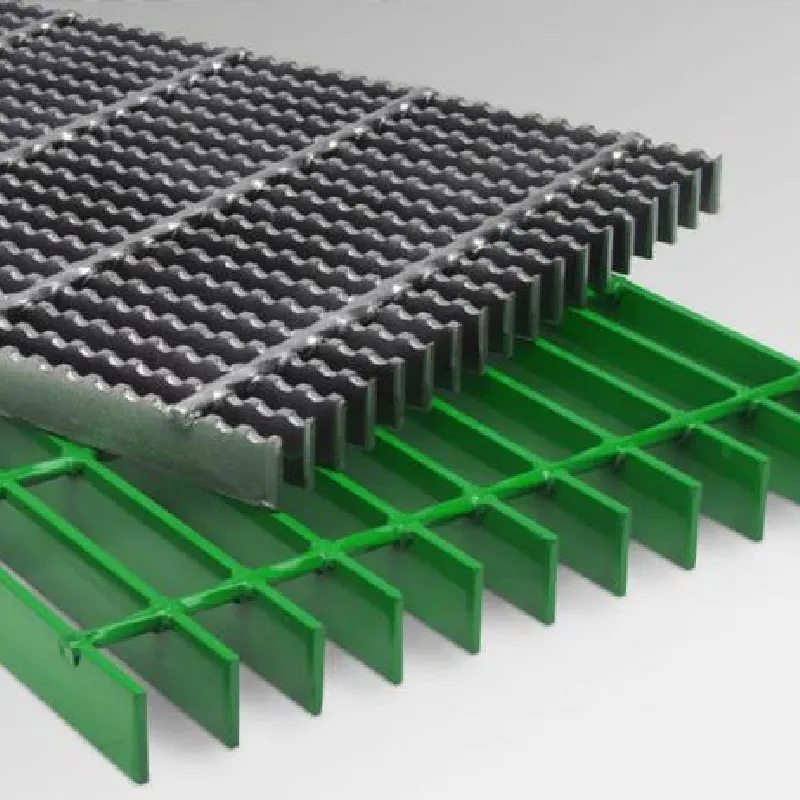

high pressure shaft.Additionally, floor grating panels contribute to enhanced ventilation. In areas where air circulation is critical, such as chemical processing plants and power generation facilities, these panels allow for optimal airflow. By preventing the buildup of heat and harmful vapors, they help to create a safer working environment while improving overall efficiency. Moreover, the open design of grating panels can also aid in the dispersal of light, making dark areas more illuminated and safe for employees.

floor grating panels