Current location:Home > seal kit pump >

seal kit pump

2025-08-14 19:13

2025-08-14 19:00

2025-08-14 18:31

2025-08-14 18:30

2025-08-14 18:07

2025-08-14 18:07

2025-08-14 17:46

2025-08-14 17:15

2025-08-14 17:00

2025-08-14 16:53

Latest articles

Regular maintenance and inspection of oil seals are essential to ensure optimal performance and prevent potential leaks. Oil seals should be checked for wear and tear, cracks, or other signs of damage that could compromise their effectiveness. Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

70 90 10 oil seal.

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks

Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks Replacing oil seals at regular intervals, typically every 10,000 miles or annually, can help prolong the life of equipment and prevent leaks 70 90 10 oil seal.

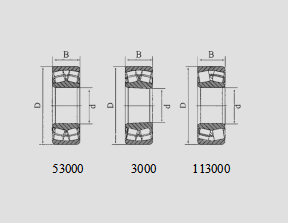

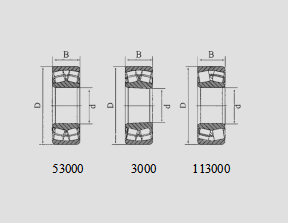

70 90 10 oil seal.Next, the inner and outer diameters determine the bearing's fit within the housing or shaft angular contact ball bearing size chart. It's crucial to choose a size that allows for proper clearance or interference, ensuring smooth rotation without excessive play or stress.

angular contact ball bearing size chart. It's crucial to choose a size that allows for proper clearance or interference, ensuring smooth rotation without excessive play or stress.

angular contact ball bearing size chart. It's crucial to choose a size that allows for proper clearance or interference, ensuring smooth rotation without excessive play or stress.

angular contact ball bearing size chart. It's crucial to choose a size that allows for proper clearance or interference, ensuring smooth rotation without excessive play or stress.