Current location:Home > hydraulic jack seal repair kit >

hydraulic jack seal repair kit

2025-08-14 07:09

2025-08-14 07:00

2025-08-14 06:42

2025-08-14 06:25

2025-08-14 06:06

2025-08-14 05:37

2025-08-14 05:35

2025-08-14 05:19

2025-08-14 05:11

2025-08-14 04:41

Latest articles

Choosing the right motor seal kit requires attention to detail. Manufacturers typically provide specifications for the correct type and size of seals needed for their motors Manufacturers typically provide specifications for the correct type and size of seals needed for their motors Manufacturers typically provide specifications for the correct type and size of seals needed for their motors Manufacturers typically provide specifications for the correct type and size of seals needed for their motors

Manufacturers typically provide specifications for the correct type and size of seals needed for their motors Manufacturers typically provide specifications for the correct type and size of seals needed for their motors motor seal kit. Using a generic seal kit could result in suboptimal performance or even damage to the motor. High-quality seal kits are made from materials such as Viton, silicone, or EPDM rubber, which offer excellent resistance to oil, heat, and ozone.

motor seal kit. Using a generic seal kit could result in suboptimal performance or even damage to the motor. High-quality seal kits are made from materials such as Viton, silicone, or EPDM rubber, which offer excellent resistance to oil, heat, and ozone.

Manufacturers typically provide specifications for the correct type and size of seals needed for their motors Manufacturers typically provide specifications for the correct type and size of seals needed for their motors

Manufacturers typically provide specifications for the correct type and size of seals needed for their motors Manufacturers typically provide specifications for the correct type and size of seals needed for their motors motor seal kit. Using a generic seal kit could result in suboptimal performance or even damage to the motor. High-quality seal kits are made from materials such as Viton, silicone, or EPDM rubber, which offer excellent resistance to oil, heat, and ozone.

motor seal kit. Using a generic seal kit could result in suboptimal performance or even damage to the motor. High-quality seal kits are made from materials such as Viton, silicone, or EPDM rubber, which offer excellent resistance to oil, heat, and ozone.But the dkb seal is not just a skilled hunter - it is also a social creature, forming close bonds with its fellow seals. It is often seen playing and frolicking with them in the water, engaging in friendly competitions and games. Its playful nature and friendly demeanor make it a beloved member of the seal community.

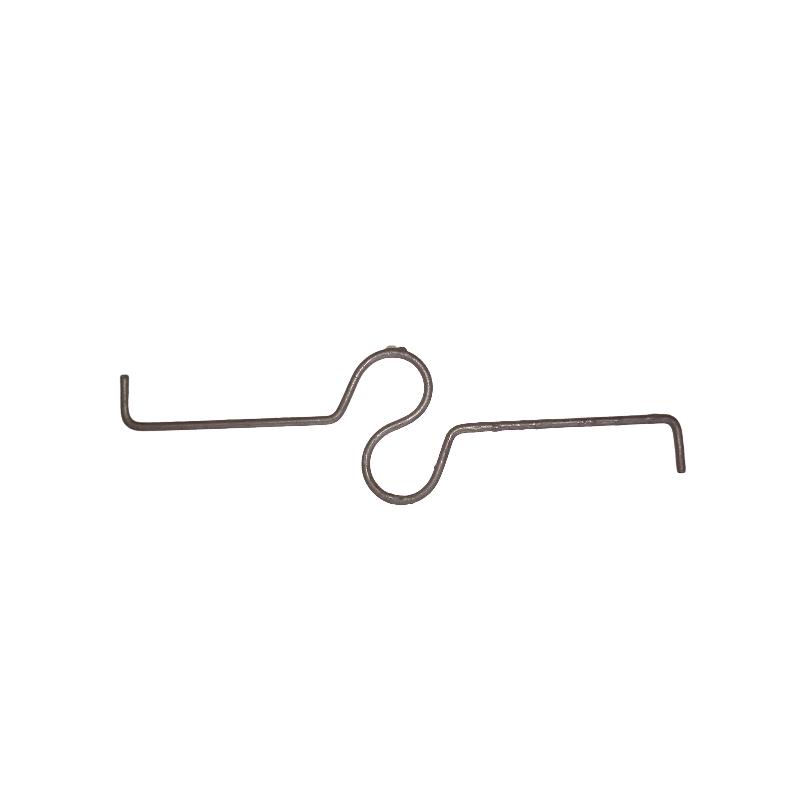

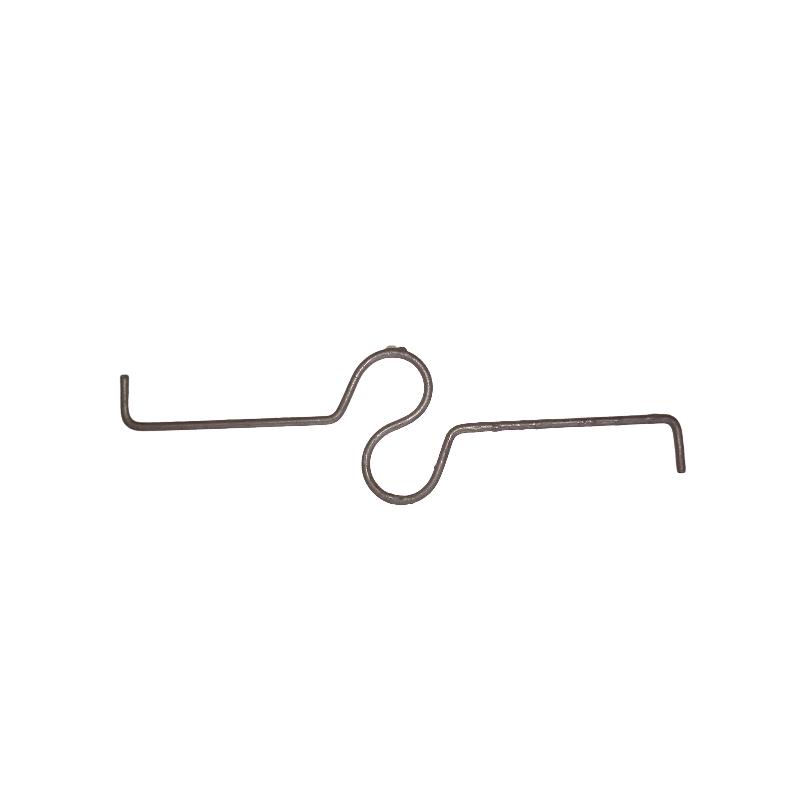

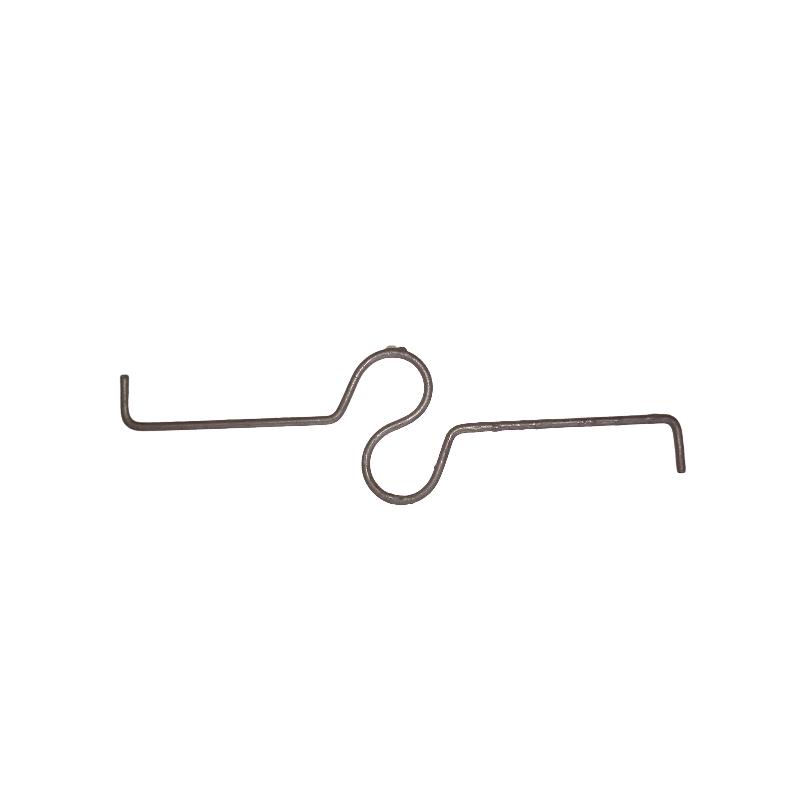

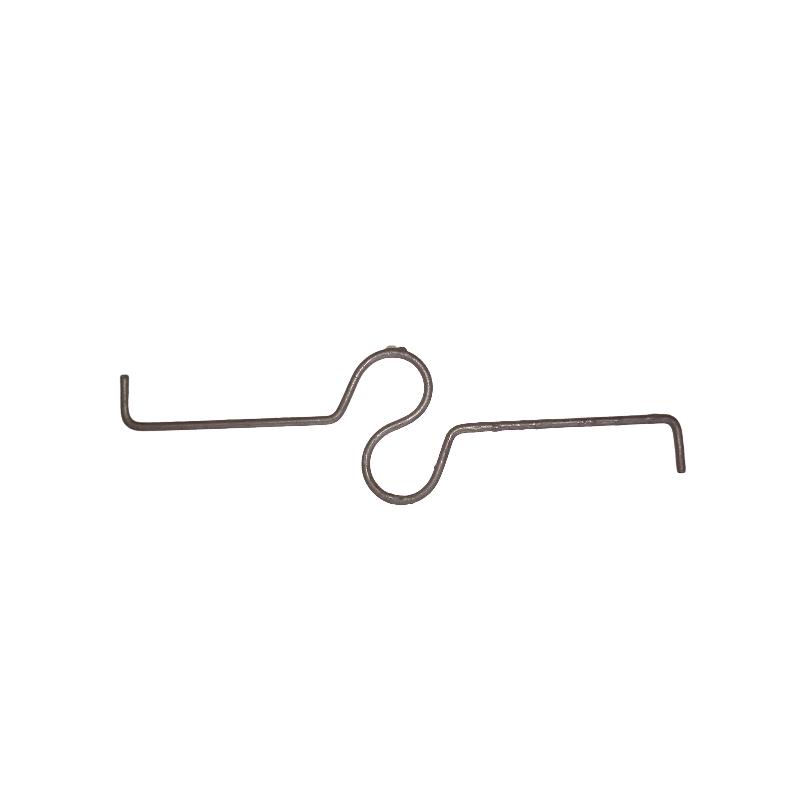

The primary function of wall ties is to transfer lateral loads, such as wind pressure, from one leaf of the wall to the other, maintaining the overall stability of the structure. They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.

wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.

wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity.Once the cage is assembled, carefully place it over the tomato plant installing a tomato cage. Make sure the cage is centered over the plant and that the wires are taut but not too tight, as this can damage the plant. If your cage has a center pole, insert it into the ground about 18 inches away from the plant.

installing a tomato cage. Make sure the cage is centered over the plant and that the wires are taut but not too tight, as this can damage the plant. If your cage has a center pole, insert it into the ground about 18 inches away from the plant.

installing a tomato cage. Make sure the cage is centered over the plant and that the wires are taut but not too tight, as this can damage the plant. If your cage has a center pole, insert it into the ground about 18 inches away from the plant.

installing a tomato cage. Make sure the cage is centered over the plant and that the wires are taut but not too tight, as this can damage the plant. If your cage has a center pole, insert it into the ground about 18 inches away from the plant.