Current location:Home > 20 35 7 oil seal >

20 35 7 oil seal

2025-08-14 16:05

2025-08-14 16:04

2025-08-14 16:01

2025-08-14 15:51

2025-08-14 15:17

2025-08-14 15:09

2025-08-14 15:07

2025-08-14 15:05

2025-08-14 14:35

2025-08-14 14:28

Latest articles

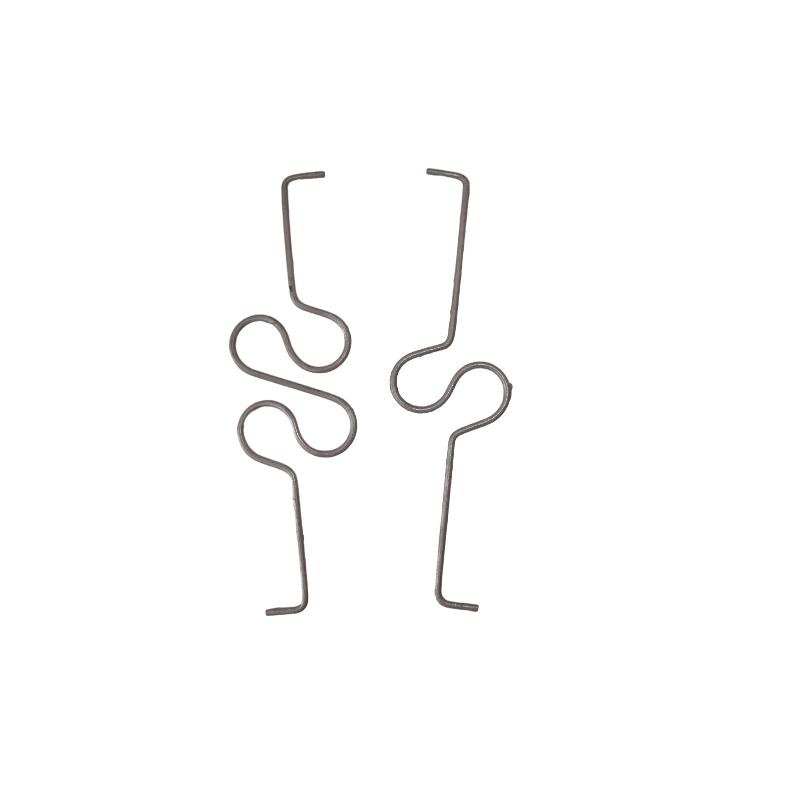

One of the key advantages of butterfly cavity wall ties is their adaptability. They can be used in a variety of construction materials, including brick, blockwork, and concrete, making them versatile for different types of projects. Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs

Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs butterfly cavity wall ties.

butterfly cavity wall ties.

Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs

Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs Moreover, their non-corrosive properties, often being made from materials like stainless steel or galvanized steel, ensure a long lifespan and reduced maintenance costs butterfly cavity wall ties.

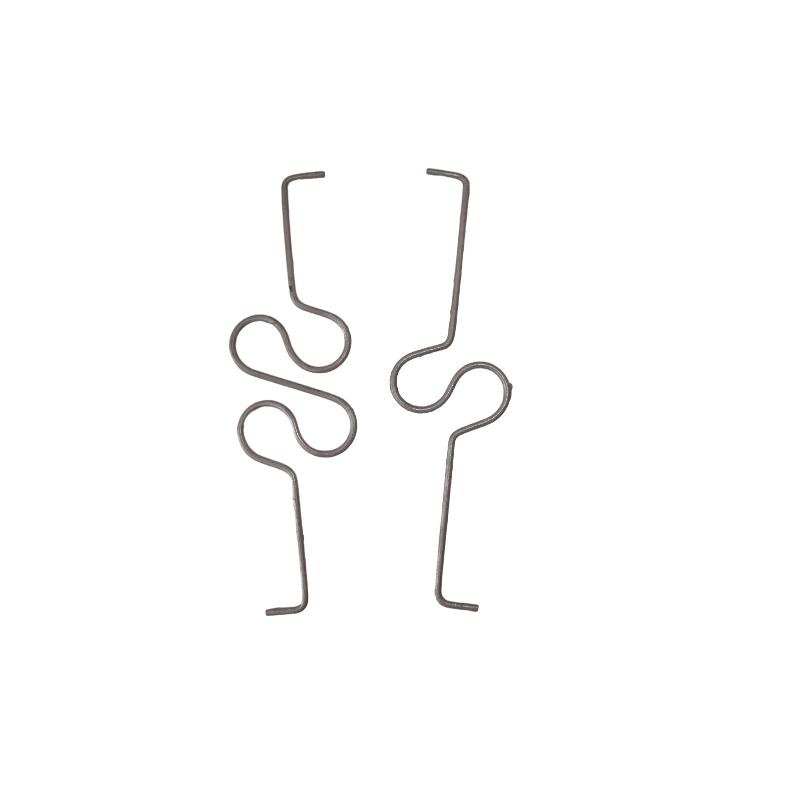

butterfly cavity wall ties.One of the key benefits of using galvanized wall ties is their durability

galvanized wall ties. Unlike other types of wall ties that may corrode over time, galvanized wall ties are resistant to rust and corrosion, ensuring that they remain intact and provide continuous support to the walls. This durability is crucial in maintaining the structural integrity of a building and preventing any potential issues that may arise due to weak or deteriorating wall ties.

galvanized wall ties. Unlike other types of wall ties that may corrode over time, galvanized wall ties are resistant to rust and corrosion, ensuring that they remain intact and provide continuous support to the walls. This durability is crucial in maintaining the structural integrity of a building and preventing any potential issues that may arise due to weak or deteriorating wall ties.

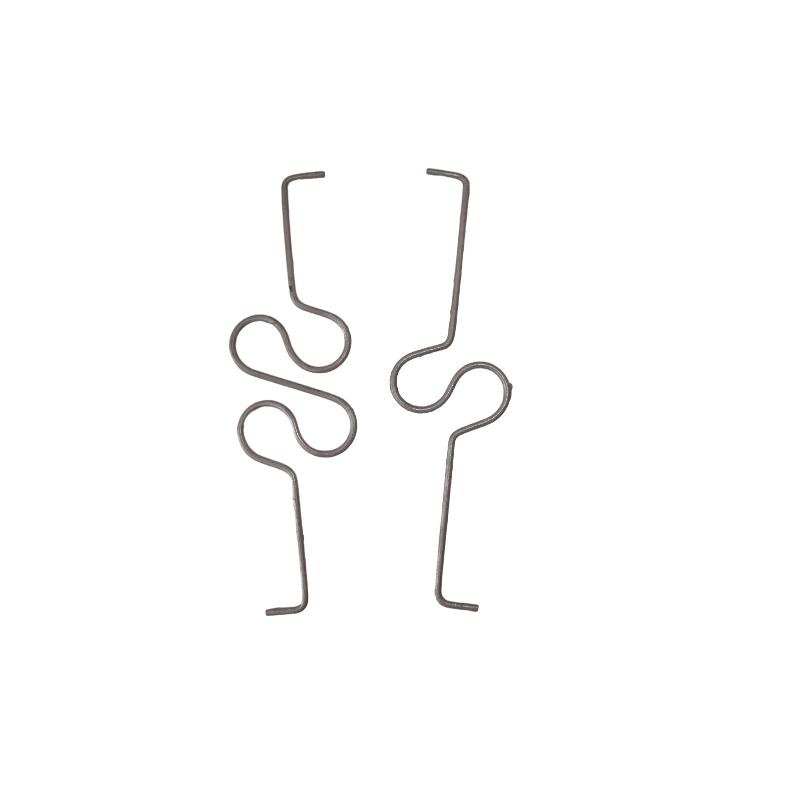

The type of construction also influences the spacing of brick veneer ties. In buildings with a lightweight structure, such as wood frame construction, the ties may need to be spaced closer together to ensure that the brick veneer is properly supported. In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties

In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties brick veneer tie spacing.

brick veneer tie spacing.

In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties

In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties brick veneer tie spacing.

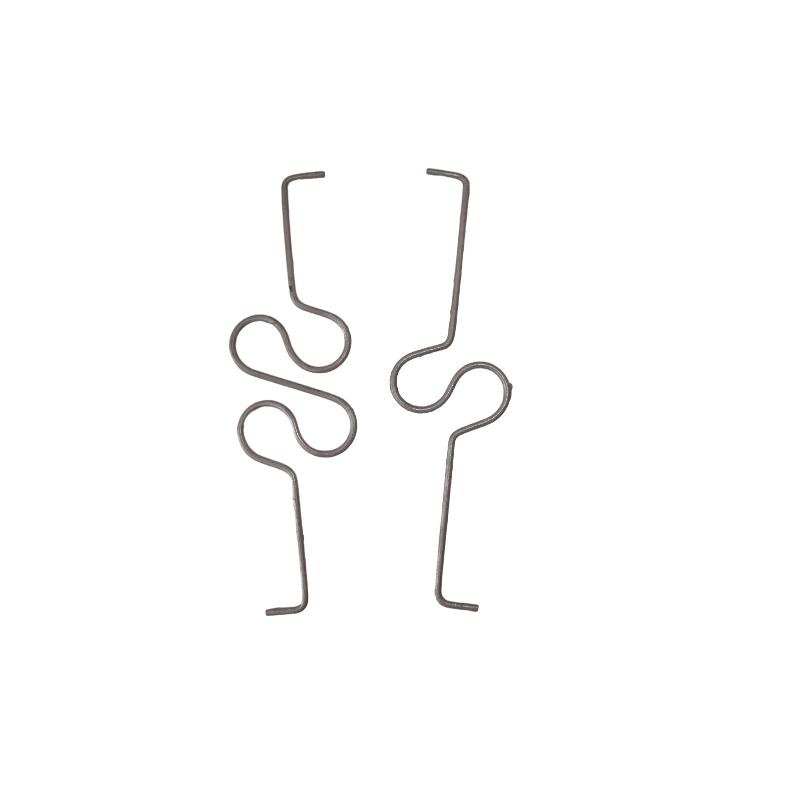

brick veneer tie spacing.The primary function of mesh reinforcement in concrete slabs is to control cracking and reduce the risk of structural failure. Concrete tends to crack due to a variety of factors, including shrinkage, temperature changes, and external loads. By adding mesh reinforcement, the tensile strength of the concrete is increased, allowing it to better resist cracking and maintain its structural integrity over time. Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points

Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points mesh for concrete slab.

mesh for concrete slab.

Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points

Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points mesh for concrete slab.

mesh for concrete slab.