Current location:Home > wiper system >

wiper system

2025-08-14 22:12

2025-08-14 21:51

2025-08-14 21:43

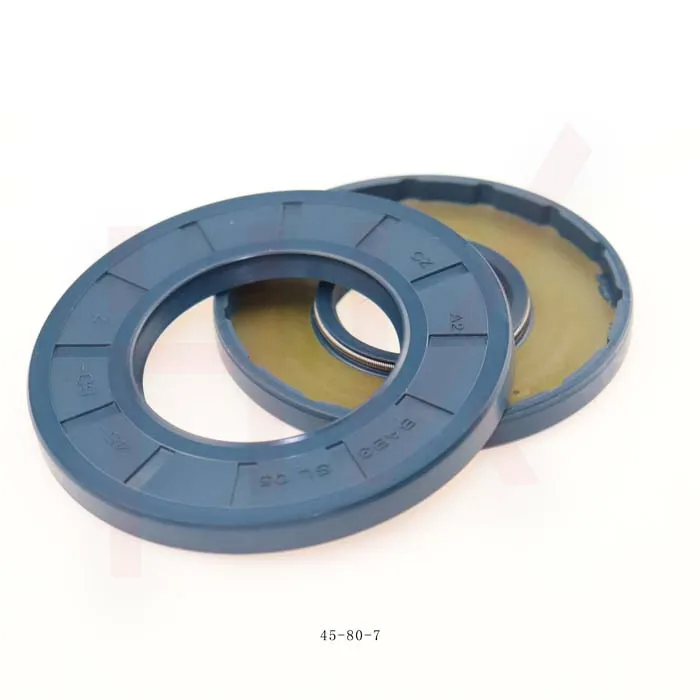

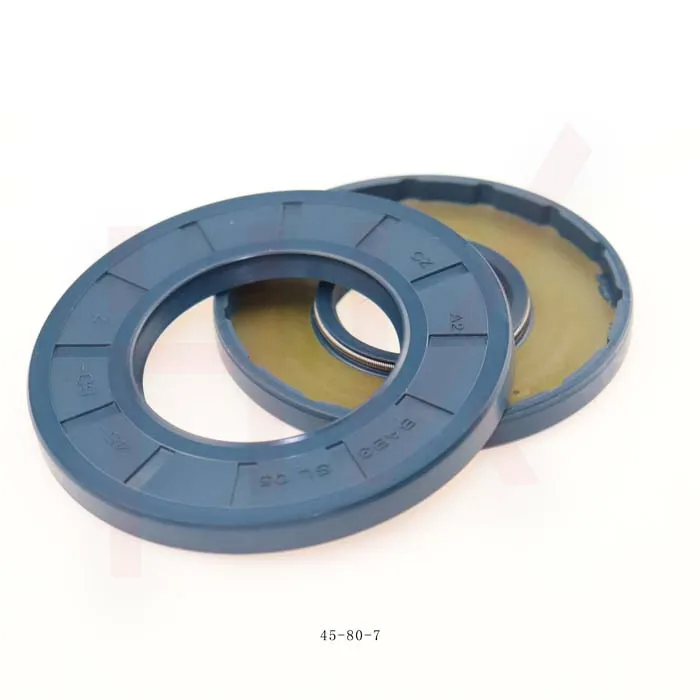

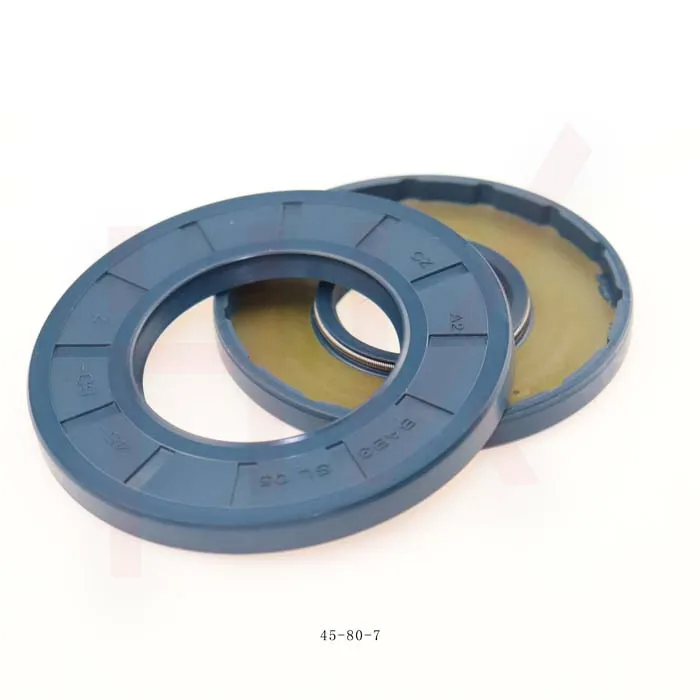

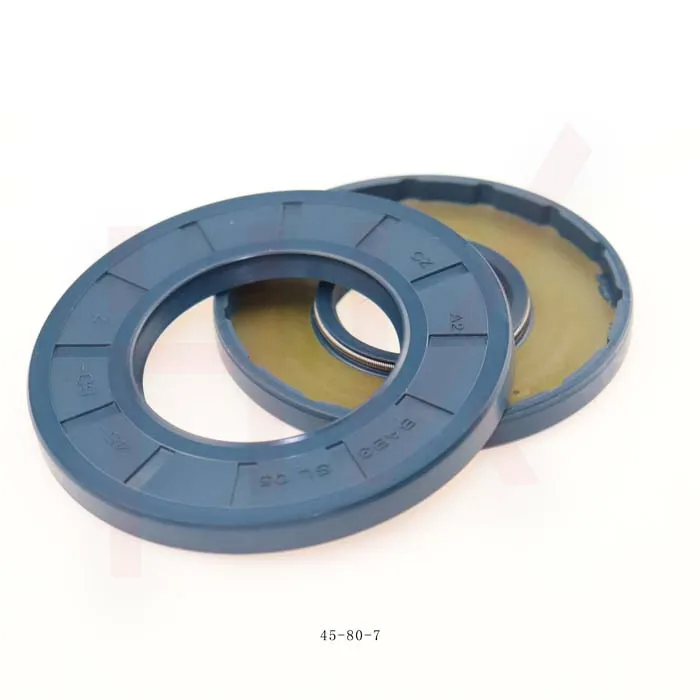

Maintenance of hydraulic shaft seals is equally important hydraulic shaft seal. Regular inspections can identify wear before it leads to failure, preventing costly downtime and repairs. Proper installation is crucial; the seal must be aligned correctly with the shaft and have the right amount of tension to avoid excessive wear or leakage. Additionally, the compatibility of the seal material with the fluid it contains is essential to prevent chemical degradation.

hydraulic shaft seal. Regular inspections can identify wear before it leads to failure, preventing costly downtime and repairs. Proper installation is crucial; the seal must be aligned correctly with the shaft and have the right amount of tension to avoid excessive wear or leakage. Additionally, the compatibility of the seal material with the fluid it contains is essential to prevent chemical degradation.

hydraulic shaft seal. Regular inspections can identify wear before it leads to failure, preventing costly downtime and repairs. Proper installation is crucial; the seal must be aligned correctly with the shaft and have the right amount of tension to avoid excessive wear or leakage. Additionally, the compatibility of the seal material with the fluid it contains is essential to prevent chemical degradation.

hydraulic shaft seal. Regular inspections can identify wear before it leads to failure, preventing costly downtime and repairs. Proper installation is crucial; the seal must be aligned correctly with the shaft and have the right amount of tension to avoid excessive wear or leakage. Additionally, the compatibility of the seal material with the fluid it contains is essential to prevent chemical degradation.

...

2025-08-14 21:28

2025-08-14 21:22

2025-08-14 21:06

2025-08-14 20:35

Moreover, hyd cylinder seals were not just utilitarian; they were also miniature works of art. The skilled artisans who crafted them displayed remarkable proficiency in their miniature depictions, making them valuable even today for historians and art enthusiasts. The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies

The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies hyd cylinder seals.

hyd cylinder seals.

The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies

The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies hyd cylinder seals.

hyd cylinder seals.

...

2025-08-14 19:49

2025-08-14 19:33

Furthermore, dust lip seals also contribute to the overall efficiency and reliability of machinery

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

dust lip seal. By sealing off critical components from external contaminants, these seals help to reduce maintenance requirements and downtime, saving time and money in the long run. With a properly functioning dust lip seal in place, machinery operators can rest assured that their equipment is protected and operating at peak performance levels.

...

2025-08-14 19:33

Latest articles

Proper installation of oil seals is crucial to ensure they function effectively. Before installing a new oil seal, it is important to clean the shaft and housing to remove any dirt or debris that could damage the seal

17x30x7 oil seal. The seal should be pressed into place using a proper installation tool to avoid any damage to the sealing element.

17x30x7 oil seal. The seal should be pressed into place using a proper installation tool to avoid any damage to the sealing element.

In the automotive industry, coated float glass is widely used in the production of windshields and windows coated float glass. The combination of thermal insulation and safety features makes it an excellent choice for vehicles operating in all weather conditions. The coating also helps to reduce glare, improving visibility and enhancing the overall driving experience.

coated float glass. The combination of thermal insulation and safety features makes it an excellent choice for vehicles operating in all weather conditions. The coating also helps to reduce glare, improving visibility and enhancing the overall driving experience.

coated float glass. The combination of thermal insulation and safety features makes it an excellent choice for vehicles operating in all weather conditions. The coating also helps to reduce glare, improving visibility and enhancing the overall driving experience.

coated float glass. The combination of thermal insulation and safety features makes it an excellent choice for vehicles operating in all weather conditions. The coating also helps to reduce glare, improving visibility and enhancing the overall driving experience.