Current location:Home > rotary lip seal >

rotary lip seal

2025-08-14 05:20

2025-08-14 05:12

2025-08-14 04:34

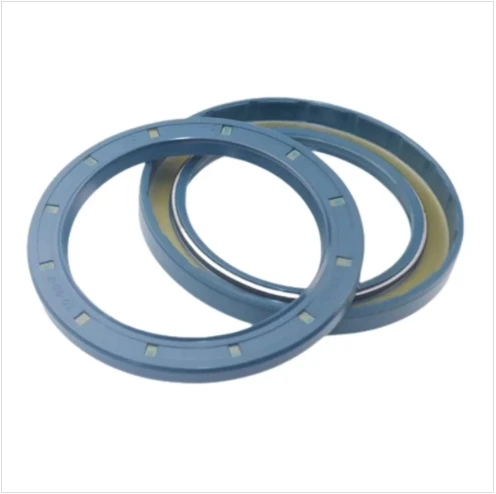

To address these challenges, high pressure shaft seals are typically made from materials such as high-strength metals, ceramics, or specially formulated elastomers that can withstand high pressures and temperatures

high pressure shaft seals. These materials are often combined with advanced sealing technologies, such as spring-loaded designs or lip seals, to provide the necessary sealing power while minimizing friction and heat generation.

high pressure shaft seals. These materials are often combined with advanced sealing technologies, such as spring-loaded designs or lip seals, to provide the necessary sealing power while minimizing friction and heat generation.

...

2025-08-14 03:57

Replacing the seal kit is a relatively straightforward process, although some mechanical knowledge is beneficial bottle jack seal kit. It involves disassembling the jack, removing the old seals, cleaning the surfaces, and installing the new ones. Always refer to the manufacturer's instructions or seek professional help if unsure.

bottle jack seal kit. It involves disassembling the jack, removing the old seals, cleaning the surfaces, and installing the new ones. Always refer to the manufacturer's instructions or seek professional help if unsure.

bottle jack seal kit. It involves disassembling the jack, removing the old seals, cleaning the surfaces, and installing the new ones. Always refer to the manufacturer's instructions or seek professional help if unsure.

bottle jack seal kit. It involves disassembling the jack, removing the old seals, cleaning the surfaces, and installing the new ones. Always refer to the manufacturer's instructions or seek professional help if unsure.

...

2025-08-14 03:54

2025-08-14 03:45

2025-08-14 03:38

2025-08-14 03:01

2025-08-14 02:58

When selecting a hub seal by size, it is important to consider the diameter of the hub, the type of material being sealed, and the operating conditions of the equipment hub seals by size. It is also important to ensure that the seal meets any relevant industry standards for performance and safety.

hub seals by size. It is also important to ensure that the seal meets any relevant industry standards for performance and safety.

hub seals by size. It is also important to ensure that the seal meets any relevant industry standards for performance and safety.

hub seals by size. It is also important to ensure that the seal meets any relevant industry standards for performance and safety.

...

2025-08-14 02:55

Latest articles

In addition to its sealing function, hub rubber seals also play a crucial role in reducing friction and wear in the machinery hub rubber seal. By providing a smooth surface for the rotating parts to glide on, the seals help to minimize friction, heat, and wear, thus extending the lifespan of the equipment.

hub rubber seal. By providing a smooth surface for the rotating parts to glide on, the seals help to minimize friction, heat, and wear, thus extending the lifespan of the equipment.

hub rubber seal. By providing a smooth surface for the rotating parts to glide on, the seals help to minimize friction, heat, and wear, thus extending the lifespan of the equipment.

hub rubber seal. By providing a smooth surface for the rotating parts to glide on, the seals help to minimize friction, heat, and wear, thus extending the lifespan of the equipment.Moreover, the integration of color steel edges can contribute to the overall durability and corrosion resistance of products. The coloring process used for these edges often includes protective coatings that not only ensure vibrant visuals but also extend the lifespan of the steel. This dual benefit makes OEM color steel edges an attractive option for industries ranging from automotive to construction and appliances.

oem color steel edge

1. Protection Against Moisture One of the primary functions of a floor seal is to create a moisture barrier. Floor seals made from high-quality materials effectively prevent water from seeping into the flooring, which can lead to warping, mold growth, and other damage.

high quality floor strip and seal