14x22x5 oil seal

30x42x7 oil seal. In automotive engines, for instance, they prevent engine oil from seeping out, ensuring efficient lubrication and reducing the risk of component failure. In industrial machinery, they help maintain the cleanliness of hydraulic systems, preventing contamination and prolonging the life of pumps and motors.

30x42x7 oil seal. In automotive engines, for instance, they prevent engine oil from seeping out, ensuring efficient lubrication and reducing the risk of component failure. In industrial machinery, they help maintain the cleanliness of hydraulic systems, preventing contamination and prolonging the life of pumps and motors.

In addition to preventing leaks, the high pressure oil rail seal kit also helps to maintain the proper level of pressure in the fuel delivery system

. This is crucial for the efficient operation of the engine and can help to prevent issues such as fuel starvation or excessive wear on the fuel injectors.high pressure oil rail seal kit

Low-quality seals may fail quickly or not provide an adequate seal, resulting in oil leaks and reduced system performance Low-quality seals may fail quickly or not provide an adequate seal, resulting in oil leaks and reduced system performance

Low-quality seals may fail quickly or not provide an adequate seal, resulting in oil leaks and reduced system performance Low-quality seals may fail quickly or not provide an adequate seal, resulting in oil leaks and reduced system performance hydraulic cylinder oil seal kit. This can lead to costly repairs and downtime, negatively impacting productivity and profitability. Therefore, it is imperative to invest in high-quality oil seal kits that are specifically designed for your hydraulic cylinder application.

hydraulic cylinder oil seal kit. This can lead to costly repairs and downtime, negatively impacting productivity and profitability. Therefore, it is imperative to invest in high-quality oil seal kits that are specifically designed for your hydraulic cylinder application. oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.

oil seal for rotating shaft. When exposed to dust, dirt, or other debris, the seal acts as a shield, preventing these particles from entering the lubrication system. This helps maintain the purity of the lubricant, ensuring optimal performance and reducing the risk of damage to the rotating shaft.3. Corrosion Resistance Fiberglass is an excellent choice for coastal areas or regions with high humidity. It does not corrode or rust like metal, ensuring that your fence remains functional and aesthetically pleasing for years to come. This characteristic is particularly important for properties near saltwater, where traditional materials may deteriorate rapidly.

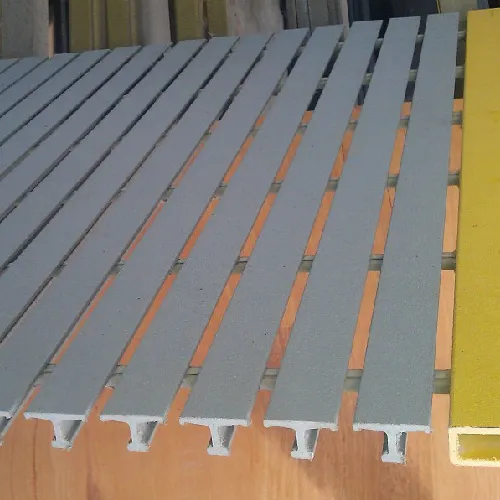

fiberglass fence rods

In terms of maintenance, SMC panel tanks are relatively low-maintenance. Their corrosion-resistant properties eliminate the need for frequent inspections and treatments that metal tanks require. When maintenance is necessary, the modular design allows for easy access to specific tank sections without disassembling the entire structure.