Current location:Home > wheel seal oil >

wheel seal oil

2025-08-14 06:22

2025-08-14 06:06

2025-08-14 05:59

2025-08-14 05:37

From an economic standpoint, motor seal kits offer significant cost savings in the long run motor seal kit. While there might be an initial investment in purchasing and installing these kits, the cost of potential downtime, repairs, or complete motor replacement due to avoidable damages far outweighs this expense. Regular maintenance and timely replacement of motor seal kits ensure that motors operate at peak efficiency, minimizing unexpected system failures that can disrupt production and incur hefty repair bills.

motor seal kit. While there might be an initial investment in purchasing and installing these kits, the cost of potential downtime, repairs, or complete motor replacement due to avoidable damages far outweighs this expense. Regular maintenance and timely replacement of motor seal kits ensure that motors operate at peak efficiency, minimizing unexpected system failures that can disrupt production and incur hefty repair bills.

motor seal kit. While there might be an initial investment in purchasing and installing these kits, the cost of potential downtime, repairs, or complete motor replacement due to avoidable damages far outweighs this expense. Regular maintenance and timely replacement of motor seal kits ensure that motors operate at peak efficiency, minimizing unexpected system failures that can disrupt production and incur hefty repair bills.

motor seal kit. While there might be an initial investment in purchasing and installing these kits, the cost of potential downtime, repairs, or complete motor replacement due to avoidable damages far outweighs this expense. Regular maintenance and timely replacement of motor seal kits ensure that motors operate at peak efficiency, minimizing unexpected system failures that can disrupt production and incur hefty repair bills.

...

2025-08-14 05:35

2025-08-14 05:35

2025-08-14 04:25

Furthermore, agricultural seals can help to boost consumer confidence in the agricultural industry agricultural seals. With so much concern about the environmental and social impacts of modern agriculture, consumers are increasingly looking for products that are produced in a responsible and sustainable manner. Agricultural seals provide them with a reliable way to identify these products and make informed purchasing decisions.

agricultural seals. With so much concern about the environmental and social impacts of modern agriculture, consumers are increasingly looking for products that are produced in a responsible and sustainable manner. Agricultural seals provide them with a reliable way to identify these products and make informed purchasing decisions.

agricultural seals. With so much concern about the environmental and social impacts of modern agriculture, consumers are increasingly looking for products that are produced in a responsible and sustainable manner. Agricultural seals provide them with a reliable way to identify these products and make informed purchasing decisions.

agricultural seals. With so much concern about the environmental and social impacts of modern agriculture, consumers are increasingly looking for products that are produced in a responsible and sustainable manner. Agricultural seals provide them with a reliable way to identify these products and make informed purchasing decisions.

...

2025-08-14 03:54

2025-08-14 03:53

2025-08-14 03:51

Latest articles

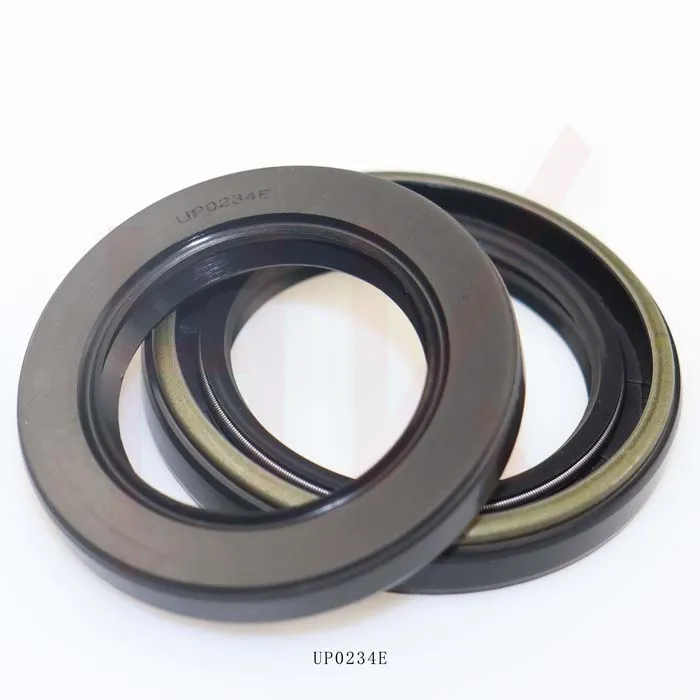

The price of oil seals can range from a few dollars to over a hundred dollars, depending on various factors. One of the primary factors influencing the price is the material used in the construction of the seal. Oil seals can be made from materials such as nitrile rubber, silicone, polyacrylate, and fluorocarbon. Each material has its own set of properties, such as resistance to heat, oil, and chemicals, which can impact the overall performance and cost of the seal.

The installation process of flat rib metal lath involves securing it to the underlying structure with fasteners, followed by the application of a scratch coat, a middle coat, and finally a finish coat flat rib metal lath. The ribs on the lath provide a mechanical key for the plaster or stucco, enhancing the bond and overall adhesion.

flat rib metal lath. The ribs on the lath provide a mechanical key for the plaster or stucco, enhancing the bond and overall adhesion.

flat rib metal lath. The ribs on the lath provide a mechanical key for the plaster or stucco, enhancing the bond and overall adhesion.

flat rib metal lath. The ribs on the lath provide a mechanical key for the plaster or stucco, enhancing the bond and overall adhesion.One common type of extension spring is the 12% extension spring, which refers to the amount the spring can stretch beyond its original length before reaching its elastic limit. This type of spring is known for its flexibility and ability to handle a wide range of loads and applications. The 12% extension spring is commonly used in industrial settings where heavy loads need to be supported or in situations where a large amount of force needs to be absorbed.

Another advantage of conical coil springs is their ability to store and release energy efficiently. The cone shape of the spring allows for a more compact design that can store a large amount of energy in a smaller space compared to a cylindrical spring of the same size

conical coil spring. This makes conical coil springs well-suited for applications where space is limited, such as in small engines or machinery.

conical coil spring. This makes conical coil springs well-suited for applications where space is limited, such as in small engines or machinery.