Current location:Home > hydraulic motor oil seal >

hydraulic motor oil seal

2025-08-15 07:02

2025-08-15 06:38

2025-08-15 06:15

2025-08-15 06:15

2025-08-15 06:04

2025-08-15 05:36

2025-08-15 05:25

2025-08-15 05:25

2025-08-15 05:12

2025-08-15 05:10

Latest articles

To ensure that wheel bearing grease seals are functioning properly, it is important to inspect them regularly for any signs of wear or damage. The seals should be free of cracks, tears, or deformities that could allow grease to leak out or contaminants to enter the bearings

wheel bearing grease seal. If any issues are detected, the seals should be replaced promptly to prevent further damage to the bearings.

wheel bearing grease seal. If any issues are detected, the seals should be replaced promptly to prevent further damage to the bearings.

In addition to these, there are also rod seals, wiper seals, and scraper seals available for sale hydraulic cylinder seals for sale. Rod seals prevent fluid from leaking out of the cylinder while wiper seals and scraper seals keep contaminants from entering, extending the life of the hydraulic system.

hydraulic cylinder seals for sale. Rod seals prevent fluid from leaking out of the cylinder while wiper seals and scraper seals keep contaminants from entering, extending the life of the hydraulic system.

hydraulic cylinder seals for sale. Rod seals prevent fluid from leaking out of the cylinder while wiper seals and scraper seals keep contaminants from entering, extending the life of the hydraulic system.

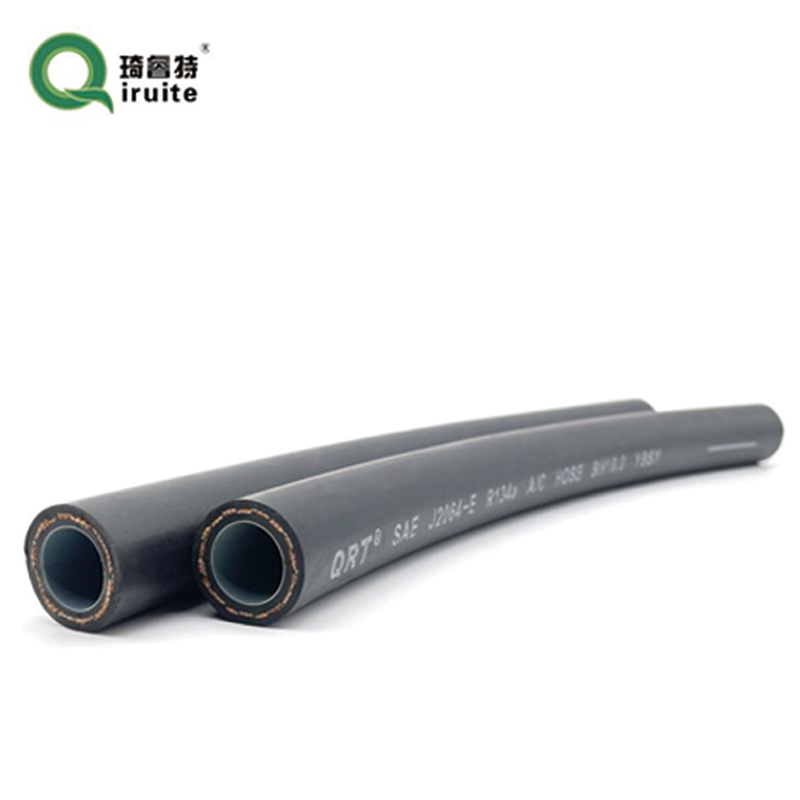

hydraulic cylinder seals for sale. Rod seals prevent fluid from leaking out of the cylinder while wiper seals and scraper seals keep contaminants from entering, extending the life of the hydraulic system.2. Attach the quick-connect fitting on the R134a fill hose to the refrigerant port

r134a fill hose. Ensure that the fitting is securely attached to prevent leaks.

r134a fill hose. Ensure that the fitting is securely attached to prevent leaks.

4 5 8 pipe coupling. **Grooved Coupling** Grooved couplings have a groove in the coupling body that fits snugly over the end of a pipe. They are commonly used in irrigation systems and can withstand moderate pressures.

5 8 pipe coupling. **Grooved Coupling** Grooved couplings have a groove in the coupling body that fits snugly over the end of a pipe. They are commonly used in irrigation systems and can withstand moderate pressures.

5 8 pipe coupling. **Grooved Coupling** Grooved couplings have a groove in the coupling body that fits snugly over the end of a pipe. They are commonly used in irrigation systems and can withstand moderate pressures.

5 8 pipe coupling. **Grooved Coupling** Grooved couplings have a groove in the coupling body that fits snugly over the end of a pipe. They are commonly used in irrigation systems and can withstand moderate pressures.