Current location:Home > Hebei Hankai oil seal companies >

Hebei Hankai oil seal companies

2025-08-15 02:09

2025-08-15 01:39

2025-08-15 01:35

2025-08-15 01:28

2025-08-15 01:13

2025-08-15 01:03

2025-08-15 00:34

2025-08-15 00:33

2025-08-15 00:21

2025-08-15 00:11

Latest articles

Another notable supplier is Freudenberg Sealing Technologies, renowned for their innovative sealing solutions. They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service

They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service hydraulic seal kits suppliers.

hydraulic seal kits suppliers.

They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service

They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service They offer custom-designed hydraulic seal kits that cater to unique system requirements, backed by exceptional technical support and service hydraulic seal kits suppliers.

hydraulic seal kits suppliers.The design of the tilt cylinder seal kit takes into account the rigorous demands placed on these seals in dynamic and often harsh environments. Materials used for manufacturing these seals are carefully selected for their durability, resistance to temperature extremes, and compatibility with various types of hydraulic fluids. Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications tilt cylinder seal kit.

tilt cylinder seal kit.

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications

Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications Common materials include nitrile rubber, polyurethane, and high-performance elastomers, each with its unique set of properties tailored to specific applications tilt cylinder seal kit.

tilt cylinder seal kit.Another significant benefit of metric shaft seals is their versatility metric shaft seals. These seals can be customized to fit a wide range of shaft diameters and speeds, making them suitable for use in a variety of applications across different industries. Whether you're working with pumps, turbines, compressors, or any other type of rotating machinery, there's a metric shaft seal that can meet your specific needs.

metric shaft seals. These seals can be customized to fit a wide range of shaft diameters and speeds, making them suitable for use in a variety of applications across different industries. Whether you're working with pumps, turbines, compressors, or any other type of rotating machinery, there's a metric shaft seal that can meet your specific needs.

metric shaft seals. These seals can be customized to fit a wide range of shaft diameters and speeds, making them suitable for use in a variety of applications across different industries. Whether you're working with pumps, turbines, compressors, or any other type of rotating machinery, there's a metric shaft seal that can meet your specific needs.

metric shaft seals. These seals can be customized to fit a wide range of shaft diameters and speeds, making them suitable for use in a variety of applications across different industries. Whether you're working with pumps, turbines, compressors, or any other type of rotating machinery, there's a metric shaft seal that can meet your specific needs.Another important consideration when selecting an oil seal is its size and shape. The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks

The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks 20 35 7 oil seal. In addition, the shape of the seal can vary depending on the specific requirements of the machinery. For example, lip seals have a flexible lip that extends outward to create a seal, while shaft seals encircle the shaft and are secured in place with a retaining ring.

20 35 7 oil seal. In addition, the shape of the seal can vary depending on the specific requirements of the machinery. For example, lip seals have a flexible lip that extends outward to create a seal, while shaft seals encircle the shaft and are secured in place with a retaining ring.

The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks

The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks The dimensions of the seal must be precisely tailored to fit the application, ensuring a snug fit that prevents leaks 20 35 7 oil seal. In addition, the shape of the seal can vary depending on the specific requirements of the machinery. For example, lip seals have a flexible lip that extends outward to create a seal, while shaft seals encircle the shaft and are secured in place with a retaining ring.

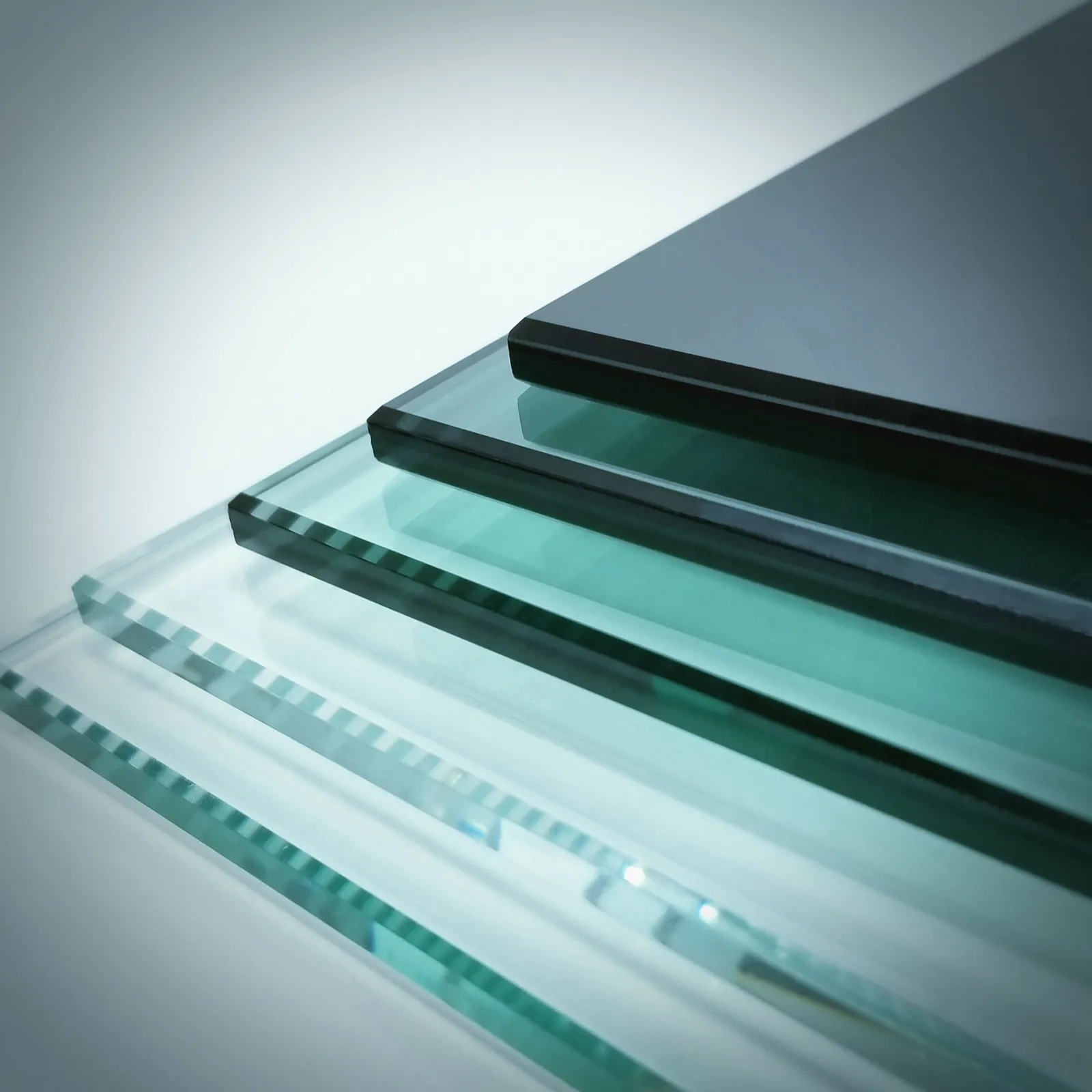

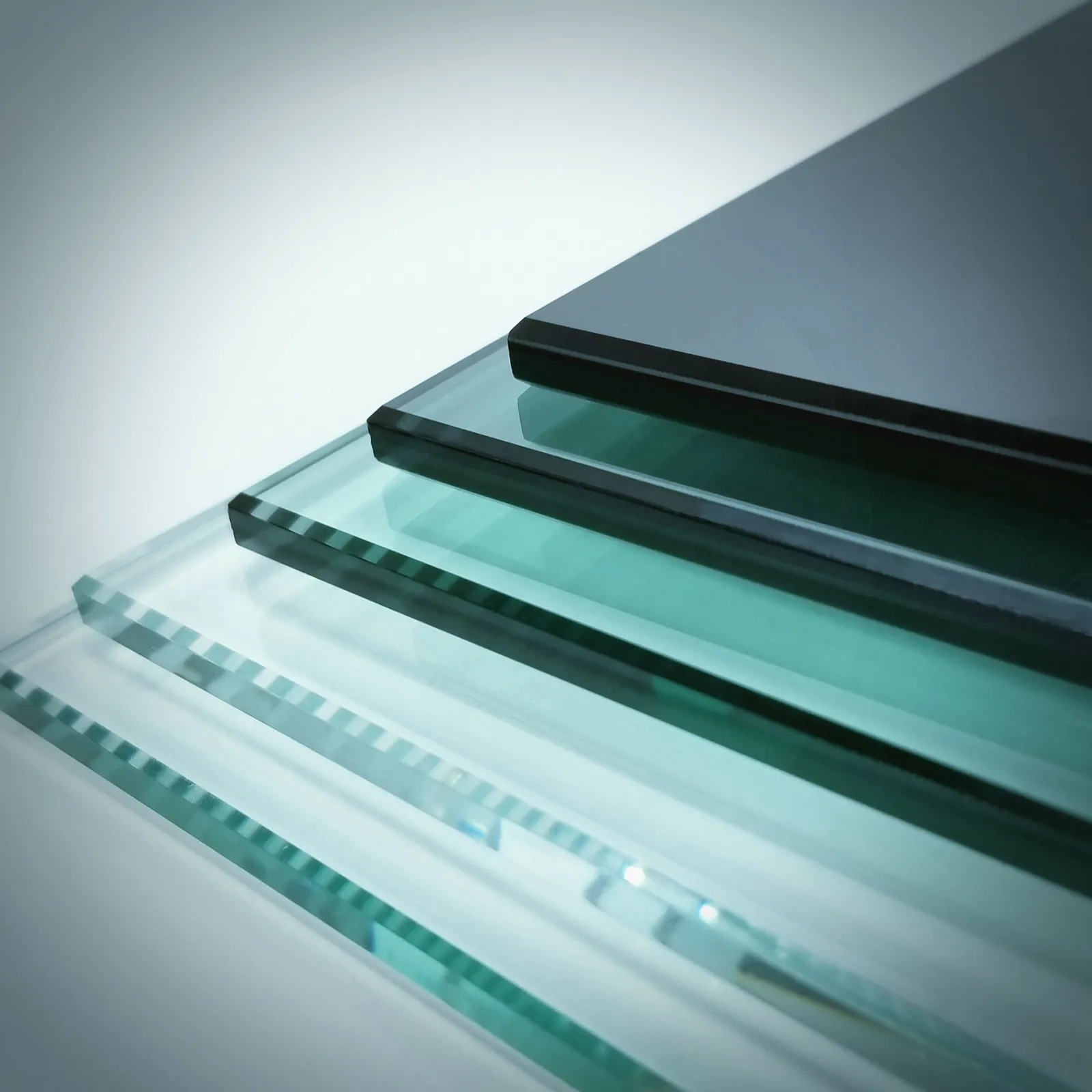

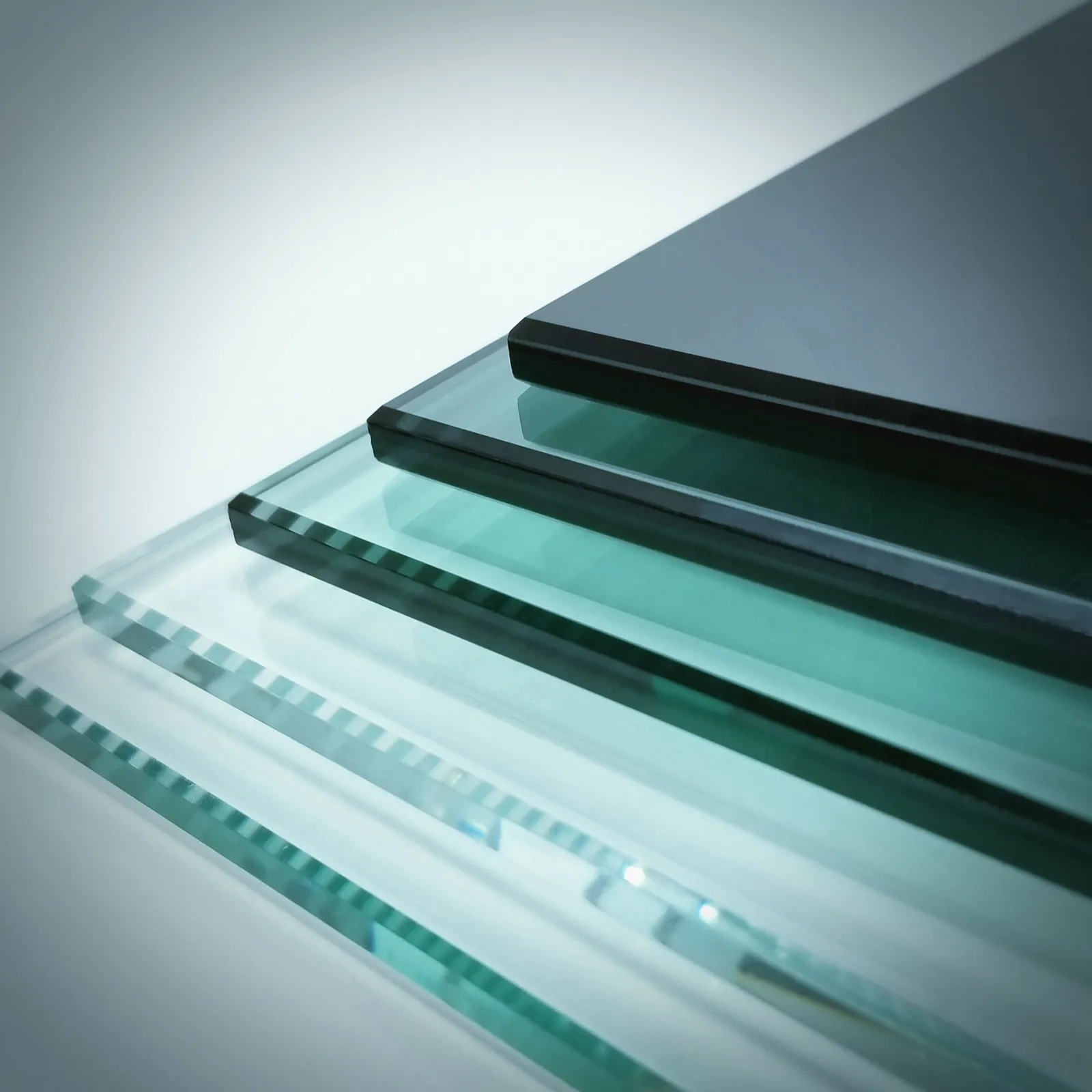

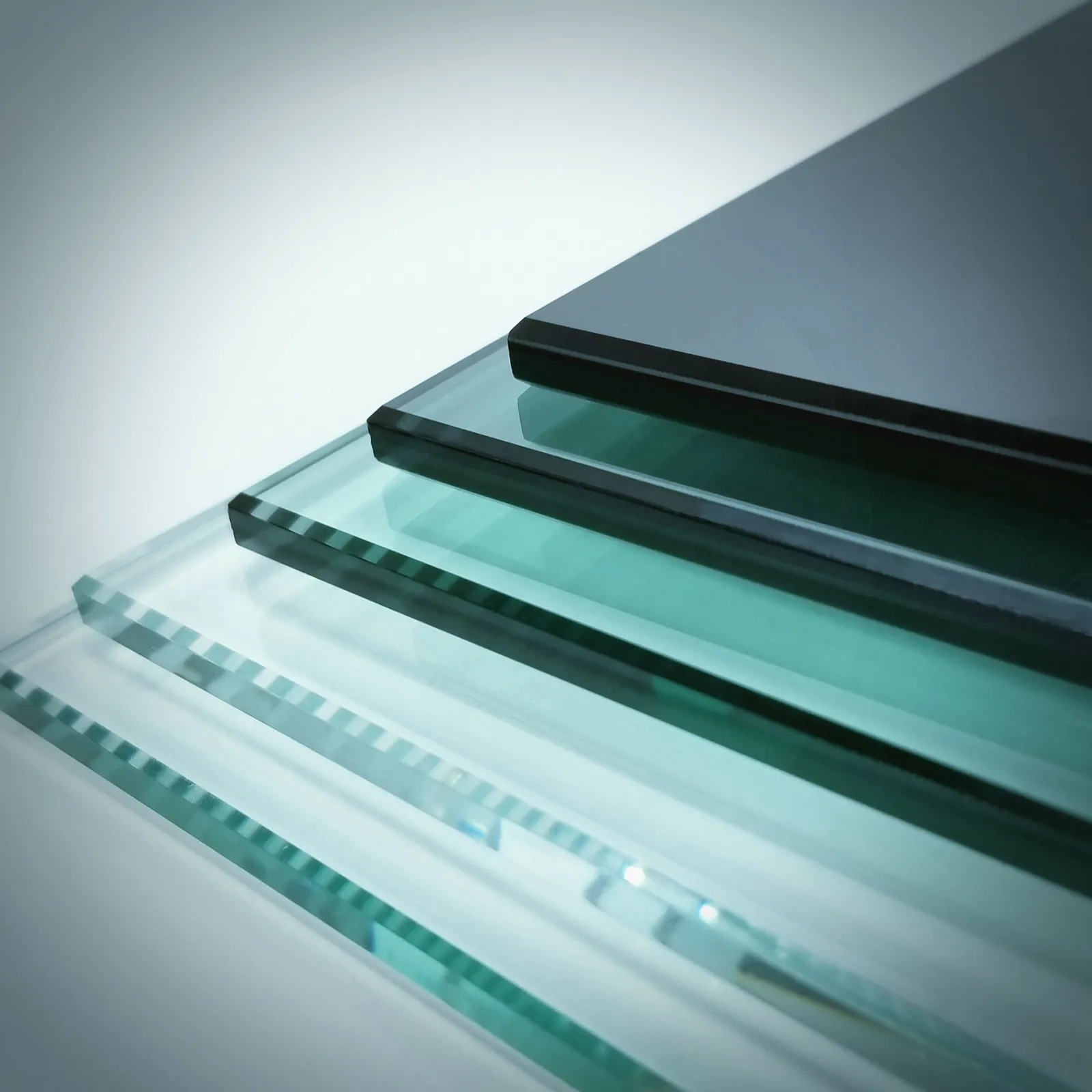

20 35 7 oil seal. In addition, the shape of the seal can vary depending on the specific requirements of the machinery. For example, lip seals have a flexible lip that extends outward to create a seal, while shaft seals encircle the shaft and are secured in place with a retaining ring.However, the science behind float glass is just as compelling as its aesthetic qualities float glass manufacturers. The interplay between the molten glass and tin requires precise control of temperature, speed, and environment to ensure optimal results. Advanced machinery and rigorous quality checks are integral to maintaining consistency and reducing imperfections.

float glass manufacturers. The interplay between the molten glass and tin requires precise control of temperature, speed, and environment to ensure optimal results. Advanced machinery and rigorous quality checks are integral to maintaining consistency and reducing imperfections.

float glass manufacturers. The interplay between the molten glass and tin requires precise control of temperature, speed, and environment to ensure optimal results. Advanced machinery and rigorous quality checks are integral to maintaining consistency and reducing imperfections.

float glass manufacturers. The interplay between the molten glass and tin requires precise control of temperature, speed, and environment to ensure optimal results. Advanced machinery and rigorous quality checks are integral to maintaining consistency and reducing imperfections.After the glass has cooled and solidified, it is carefully removed from the molds and undergoes a rigorous quality control process to ensure that it meets the factory's standards. Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless

Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless patterned glass factory.

patterned glass factory.

Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless

Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless patterned glass factory.

patterned glass factory.